This comprehensive guide will walk you through the fascinating world of aluminum refining, what happen inside an Aluminum Refinery, equipping you with knowledge to make informed decisions and partner with Cozydoor, your trusted source for high-quality aluminum materials. Prepare to gain valuable insights that will streamline your projects, enhance your competitive edge, and elevate your building masterpieces!

What is Aluminum Refining

Imagine taking the raw, unrefined bauxite ore, found in tropical and subtropical regions around the world, and transforming it into the sleek, versatile aluminum that forms the foundation of our modern structures. This is the essence of aluminum refining – a meticulous process that unlocks the incredible potential of this ubiquitous metal.

From Bauxite to Alumina: The Journey Begins

Aluminum refining starts with alumina mining. Bauxite ore, rich in aluminum oxide, is extracted from open-pit mines, like a vast treasure chest waiting to be unlocked. This ore is then transported to the refinery, where the true transformation begins.

The first stage involves the Bayer Process, a complex and fascinating chemical transformation. The bauxite is crushed, ground, and mixed with a strong caustic soda solution. This mixture is heated under pressure, dissolving the aluminum oxide while leaving behind other impurities. The dissolved aluminum oxide is then carefully separated and precipitated, forming the white, powdery substance known as alumina.

The Hall-Héroult Process: The Birth of Aluminum

Alumina, the refined aluminum oxide, is then ready for the next stage – the Hall-Héroult Process, the cornerstone of aluminum production. This process involves electrolysis, a powerful method of using electricity to break down the alumina into pure aluminum.

The alumina is dissolved in a molten salt bath, called cryolite, and subjected to a direct electric current. This current causes the aluminum ions to migrate to the cathode, where they are reduced to metallic aluminum. The molten aluminum is then collected at the bottom of the electrolysis cell, ready for further processing.

Shaping Aluminum: From Molten Metal to Useful Forms

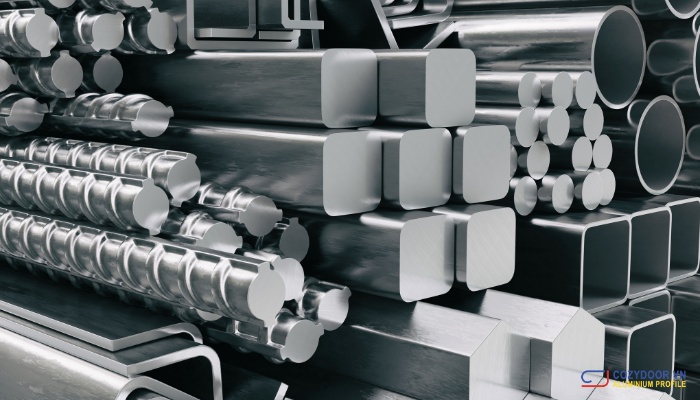

The molten aluminum, a liquid silver gleaming with potential, is then carefully poured into molds, forming ingots. These ingots are further refined, rolled, and shaped to create various forms of aluminum, such as sheets, plates, extrusions, wires, and foils. This process, known as casting and rolling, unlocks the versatility of aluminum, making it adaptable for an array of construction applications.

Different Types of Aluminum and Their Applications

The aluminum industry offers a diverse range of alloys, each with unique properties suited for specific applications. Here are some popular examples:

- Aluminum 6061: A versatile alloy commonly used in construction due to its strength, weldability, and corrosion resistance. Think beams, frames, and other structural components.

- Aluminum 6063: Another versatile alloy prized for its excellent machinability, good corrosion resistance, and strength. It’s ideal for windows, doors, and other architectural components.

- Aluminum 5052: A strong, lightweight alloy with exceptional corrosion resistance, making it perfect for marine applications, boat hulls, and other exposed structures.

- Aluminum 1100: A pure, highly malleable aluminum ideal for food containers, foil, and other applications where high purity is essential.

By understanding the different types of aluminum and their properties, you can select the optimal material for your specific construction needs, ensuring both functionality and durability.

The Environmental Impact of Aluminum Refineries

While aluminum offers numerous benefits for construction projects, it’s crucial to consider the environmental impact of its production. Aluminum refineries are energy-intensive facilities, and their operations can influence the surrounding environment.

Energy Consumption and Greenhouse Gas Emissions

Aluminum production is an energy-intensive process, requiring significant amounts of electricity to power the Hall-Héroult process. This energy consumption can lead to greenhouse gas emissions, primarily carbon dioxide, if the electricity is generated from fossil fuels.

However, Cozydoor is committed to environmentally responsible practices. We source our aluminum from refineries utilizing renewable energy sources, minimizing our carbon footprint and contributing to a greener future.

Read more Blog & New:

Waste Management and Disposal in Aluminum Refineries

Aluminum refining processes generate byproducts, such as red mud, a residue from the Bayer Process. This residue requires careful management and disposal to prevent environmental contamination.

Cozydoor prioritizes responsible waste management practices, ensuring that all byproducts are treated and disposed of according to the highest environmental standards. We believe in responsible aluminum production that safeguards our planet for generations to come.

Effects of Aluminum Refining on Water Resources

Aluminum refineries often require significant water resources for processing and cooling. Improper management can lead to water pollution and strain on local water systems.

Cozydoor collaborates with refineries employing advanced water treatment technologies, minimizing environmental impact and ensuring responsible water usage. We are committed to protecting our shared water resources for present and future generations.

Sustainable Practices and Mitigation Strategies for Environmental Impact

The aluminum industry is making strides towards sustainability, implementing innovative technologies and practices to reduce its environmental footprint. Some notable initiatives include:

- Carbon capture and storage: This technology captures carbon dioxide emissions, preventing them from entering the atmosphere.

- Energy efficiency improvements: Utilizing advanced technologies to optimize energy consumption and reduce emissions.

- Recycling aluminum: Recycling aluminum requires significantly less energy than producing it from bauxite ore. This circular economy approach minimizes environmental impact and conserves resources.

Cozydoor actively supports these sustainability initiatives, partnering with refineries that prioritize responsible practices and environmental stewardship. We believe in a future where aluminum production is both economically viable and environmentally sustainable.

Aluminum Smelters vs Refineries

While often used interchangeably, aluminum smelters and refineries play distinct roles in the aluminum production chain. Understanding these differences is key to making informed decisions for your construction projects.

The Role of Smelters in Aluminum Production

Aluminum smelters are the primary production facilities that convert alumina into molten aluminum. They utilize the Hall-Héroult process, employing high-energy electrolysis cells to extract pure aluminum from alumina. Smelters are often located near energy sources, as they require significant amounts of electricity.

The Function of Refineries in the Aluminum Supply Chain

Aluminum refineries are responsible for further refining and processing the molten aluminum produced by smelters. Refineries transform the aluminum into ingots, sheets, plates, and other forms suitable for manufacturing and construction. They also play a role in the recycling of aluminum scrap, contributing to the sustainability of the industry.

Comparing and Contrasting Smelting and Refining Processes

While both smelters and refineries are crucial components of the aluminum industry, their processes and functions differ significantly. Here’s a table summarizing key differences:

| Feature | Smelter | Refinery |

| Primary Function | Alumina to Molten Aluminum | Molten Aluminum to Ingots, Sheets, Plates, etc. |

| Key Process | Hall-Héroult Electrolysis | Casting, Rolling, Extrusion, etc. |

| Location | Typically near energy sources | Often located near manufacturing centers |

| Environmental Impact | Higher energy consumption, carbon emissions | Lower energy consumption, less environmental impact (recycling) |

The Economic Importance of Aluminum Refinery

Aluminum refineries are more than just production facilities – they are economic engines, contributing significantly to local communities and global economies.

Job Creation and Local Economic Benefits

Aluminum refineries generate numerous jobs, from skilled workers to engineers and technicians. These facilities also contribute to local economies through tax revenues, supplier contracts, and infrastructure investments.

The Importance of Aluminum in Modern Industries

Aluminum’s unique combination of lightweight, strength, corrosion resistance, and recyclability makes it a cornerstone material in diverse industries, including construction, transportation, aerospace, and packaging. This vast demand for aluminum drives the economic growth of the refining industry.

Global Aluminum Market Trends and Trade

The global aluminum market is dynamic, with production and demand driven by a multitude of factors, including economic growth, technological advancements, and government policies. Understanding these market trends is crucial for strategic decision-making in the construction industry.

Government Regulations and Their Economic Impact on Refineries

Governments play a significant role in regulating the aluminum refining industry, setting standards for environmental protection, worker safety, and product quality. These regulations can influence production costs, technology adoption, and market dynamics.

Cozydoor navigates these regulations with expertise, ensuring that our aluminum materials meet the highest quality and safety standards, while complying with all environmental and labor laws. We strive to operate within a framework that fosters responsible growth and sustainability.

A380 Aluminum Properties: 5 Ways to Slash Costs & Boost Project Timelines

Cozydoor recognizes the demands of your industry and is committed [...]

Nov

Aircraft Grade Aluminum: Strong, Lightweight, and Reliable

In the competitive landscape of industrial construction, selecting the right [...]

Nov

Mastering the Conductivity of Al for Optimal Project Success

One key factor often overlooked is the strategic selection of [...]

Nov

Unlocking the Secrets of Aluminum Ore: What is Bauxite?

Cozydoor, your trusted partner in construction materials, is here to [...]

Nov

Understanding 6061 T6 Aluminum: Key Features Explained

Are you a construction project manager seeking a robust, versatile, [...]

Nov

Density of 6061 Aluminum Explained: How It Compares to Other Metals

Is your next industrial construction project on time and within [...]

Nov

Power of Aluminium Die Casting

Are you a construction professional looking to optimize your projects [...]

Nov

The Amazing Strength of Aluminum: What You Need to Know

At Cozydoor, we understand the challenges you face in delivering [...]

Nov