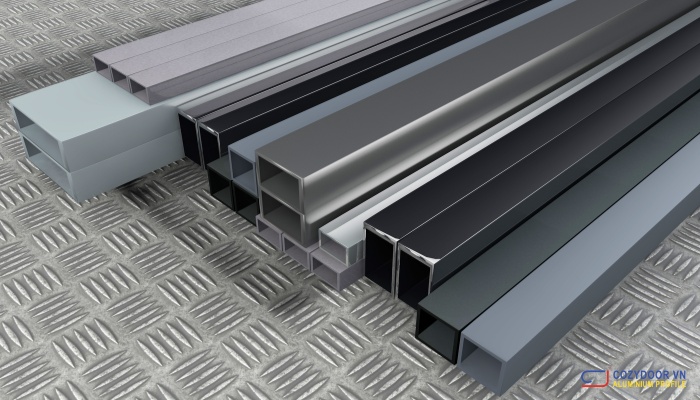

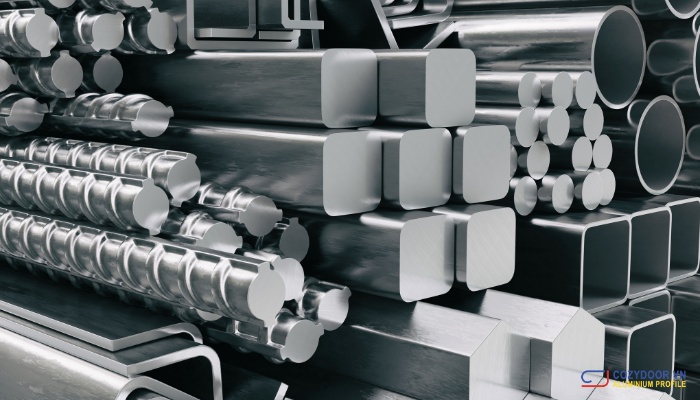

Tired of the same old construction materials? Want to elevate your projects with a blend of strength, versatility, and visual appeal? Look no further than aluminum extrusion profiles. These modern marvels are revolutionizing the way we build, offering a winning combination of durability, design freedom, and cost-effectiveness.

Aluminum Extrusion Profiles

What are Aluminum Extrusion Profiles?

Aluminum extrusion profiles are versatile and customizable building blocks, formed by forcing molten aluminum through a shaped die. This process, called extrusion, allows for the creation of complex profiles with intricate shapes and precise dimensions, far beyond what traditional fabrication methods can achieve.

How Aluminum Extrusion Profiles are Made

The process begins with a billet of aluminum, a solid block of the metal. The billet is heated to a specific temperature, becoming malleable and ready for extrusion. It’s then fed into an extrusion press, where a powerful ram forces the heated aluminum through a die – essentially a mold with the desired shape. The resulting aluminum profile emerges, ready to be further processed, cut, and fabricated into its final form.

Key Characteristics and Properties

Aluminum extrusion profiles are renowned for their exceptional properties that make them a preferred choice for construction:

- Lightweight: Aluminum is considerably lighter than steel or other common construction materials, making it easier to handle, transport, and install. This translates to reduced labor costs, faster construction timelines, and lighter building loads.

- Strength: Despite its lightness, aluminum is incredibly strong, offering a remarkable strength-to-weight ratio. This makes it ideal for building structures that are durable and capable of withstanding significant stresses.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, offering exceptional resistance to corrosion, making it an excellent choice for outdoor applications and environments prone to moisture.

- Recyclability: Aluminum is highly recyclable, making it a sustainable choice for environmentally conscious construction projects.

Advantages of Using Aluminum Extrusions

Strength and Durability

Aluminum extrusion profiles offer unmatched strength and durability, ensuring long-lasting structures that can withstand the test of time.

- Alloy Composition: The strength of aluminum extrusion profiles is influenced by the alloy used. For example, 6061 and 6063 aluminum alloys, commonly used in construction, offer a balance of strength and workability, perfect for a wide range of applications.

- Precision Engineering: The extrusion process allows for incredibly precise shaping and dimensional control, resulting in profiles that are consistent and reliable. This eliminates the need for extra reinforcement or complex welding, simplifying construction and ensuring structural integrity.

- Resistance to Wear and Tear: Aluminum’s natural resistance to abrasion and impact makes it an excellent choice for high-traffic areas and applications where durability is paramount. Whether it’s a factory floor or a busy shopping center, aluminum extrusion profiles can withstand daily wear and tear, maintaining their structural integrity for years to come.

Design Flexibility

Aluminum extrusion profiles offer unmatched design freedom, allowing architects and engineers to create unique and innovative structures.

- Custom Shapes and Profiles: The extrusion process allows for the creation of complex shapes and profiles, surpassing the limitations of traditional fabrication techniques. Whether you need intricate curves, angled cuts, or specialized slots, aluminum extrusion profiles can be customized to match any design requirement.

- Lightweight Aesthetics: The lightness of aluminum allows for the creation of slender and elegant structures without compromising strength. This opens up new possibilities for architectural designs, blending functionality with aesthetics.

- Integration of Components: Aluminum extrusion profiles can be designed to integrate seamlessly with other building components, like glass panels, insulation, and lighting fixtures. This streamlines the construction process, reducing the need for additional components and minimizing complexity.

Corrosion Resistance and Finishes

Aluminum extrusion profiles are inherently corrosion-resistant, requiring minimal maintenance and ensuring lasting beauty.

- Natural Oxide Layer: Aluminum naturally forms a protective oxide layer that shields it from corrosion. This makes it ideal for outdoor applications and environments prone to moisture, where other materials like steel might rust.

- Diverse Finishes: Beyond its natural resistance, aluminum extrusion profiles can be treated with various finishes, enhancing their aesthetics and further bolstering their corrosion resistance. Anodizing, powder coating, and painting offer a wide spectrum of colors and finishes, allowing you to personalize your projects and match your vision.

- Long-Term Durability: The combined benefits of natural corrosion resistance and protective finishes ensure that aluminum extrusion profiles maintain their visual appeal and structural integrity for years to come. This reduces maintenance costs, protects your investment, and minimizes disruptions to your business operations.

Sustainability and Recyclability

Aluminum extrusion profiles align with sustainable construction practices, minimizing environmental impact and fostering a circular economy.

- Recyclable Material: Aluminum is one of the most recyclable materials on Earth, making it a responsible choice for construction. Recycled aluminum requires significantly less energy than producing new aluminum from raw materials, reducing the carbon footprint and conserving resources.

- Reduced Waste: The extrusion process allows for precision shaping, minimizing waste during production and fabrication. This reduces material waste and promotes efficient resource utilization.

- Sustainable Construction Practices: By choosing aluminum extrusion profiles, you’re contributing to sustainable construction practices that benefit the environment and minimize your ecological footprint. This enhances your brand image, aligns with industry best practices, and demonstrates your commitment to environmental stewardship.

Read more Blog & New:

Common Applications of Aluminum Extrusion Profiles

Architectural Applications

Aluminum extrusion profiles are transforming the way we build, offering a range of solutions for architectural applications:

- Framing: Aluminum extrusion profiles are ideal for creating lightweight and strong frames for windows, doors, and curtain walls. Their versatility allows for a wide range of shapes and sizes, seamlessly integrating with other building materials.

- Curtain Walls: Aluminum extrusion profiles are often used to construct curtain walls, providing a sleek and modern aesthetic while offering excellent insulation and weather resistance.

- Sunshades and Louvers: Aluminum extrusion profiles can be shaped into intricate sunshades and louvers, providing architectural interest, maximizing natural light, and regulating heat gain.

Industrial Applications

From factories and warehouses to manufacturing facilities and logistics centers, aluminum extrusion profiles are transforming industrial settings:

- Structural Framing: Aluminum extrusion profiles are used to construct strong and durable frameworks for industrial structures, offering stability and support for heavy loads.

- Machinery and Automation: Aluminum extrusion profiles find applications in machinery and automation systems, providing lightweight and rigid components for intricate mechanisms and precise movements.

- Material Handling Systems: Aluminum extrusion profiles are commonly used in material handling systems, offering lightweight and durable components for conveyors, platforms, and storage racks.

Consumer Goods

Aluminum extrusion profiles extend their versatility to consumer goods, enhancing everyday experiences:

- Electronics: Aluminum extrusion profiles are often incorporated into electronic devices, providing lightweight and durable enclosures for laptops, smartphones, and other consumer electronics.

- Furniture: Aluminum extrusion profiles find applications in furniture design, offering lightweight and stylish frames for chairs, tables, and shelves.

- Sporting Goods: Aluminum extrusion profiles are commonly used in the construction of sporting goods, providing lightweight and durable components for bicycles, skateboards, and other athletic equipment.

DIY Projects and Custom Fabrications

Beyond large-scale industrial and architectural applications, aluminum extrusion profiles open up a world of possibilities for DIY enthusiasts and custom fabricators:

- Custom Designs: Aluminum extrusion profiles can be readily customized to your specific needs, allowing you to create unique and personalized projects.

- Cost-Effective Solutions: Aluminum extrusion profiles offer a cost-effective solution for DIY projects, providing the strength and durability you need without breaking the bank.

- Simple Assembly: Aluminum extrusion profiles are easy to work with, making them suitable for DIY projects. They often use T-slot systems, enabling effortless assembly and disassembly.

Choosing the Right Aluminum Extrusion Profile

Understanding Aluminum Alloys

Choosing the right aluminum alloy for your aluminum extrusion profiles is crucial for ensuring the strength and durability needed for your specific project.

- Common Alloys: Two popular alloys in construction are 6061 and 6063. 6061 offers excellent strength and corrosion resistance, making it ideal for structural applications. 6063 offers a good balance of strength and workability, perfect for complex shapes and profiles.

- Strength Requirements: Consider the weight your project will carry, the level of stress it will endure, and the environmental conditions it will face. Higher strength alloys are ideal for heavy-duty applications, while lower strength alloys are suitable for lighter-duty projects.

- Workability and Formability: Consider the complexity of the shapes and profiles you need. More workable alloys are easier to form and bend, making them suitable for intricate designs.

Considering Dimensions and Tolerances

The dimensions and tolerances of your aluminum extrusion profiles are crucial for a seamless integration into your project.

- Length, Width, and Height: Choose profiles with dimensions that meet the requirements of your design. Consider the overall size of the structure and the space available for installation.

- Tolerances: Tolerances refer to the allowable variation in the dimensions of the profile. Precise tolerances ensure that components fit together properly, minimizing gaps and ensuring structural integrity.

- Compatibility: Ensure that the chosen profiles are compatible with other building components, such as windows, doors, and insulation materials, for a smooth and efficient installation.

Selecting the Right Finish

Choosing the right finish for your aluminum extrusion profiles enhances their aesthetics and durability.

- Natural Finish: Aluminum has a natural, silver-gray finish that provides excellent corrosion resistance.

- Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the aluminum surface, enhancing corrosion resistance and providing a durable, attractive finish.

- Powder Coating: Powder coating involves applying a dry powder to the aluminum surface and then curing it with heat. This process creates a thick, durable finish that resists scratches and fading.

- Painting: Painting is a versatile finish that offers a wide range of colors and textures. It’s a cost-effective way to personalize your aluminum extrusion profiles and achieve a specific aesthetic.

Working with Aluminum Extrusion Suppliers

Choosing the right supplier is essential for ensuring the quality, delivery, and support needed for your project.

- Reputable Suppliers: Look for reputable suppliers with a proven track record of providing high-quality aluminum extrusion profiles. Read reviews, check certifications, and inquire about their experience in your industry.

- Communication and Collaboration: Choose a supplier who values communication and collaboration. They should be responsive to your inquiries, able to explain technical details, and willing to work with you to find the best solution for your project.

- Lead Time and Minimum Order Quantity: Consider the lead time for manufacturing and delivery, ensuring that the supplier can meet your project deadlines. Also, inquire about their minimum order quantity, ensuring it aligns with your project needs.

- Price and Value: While price is important, don’t solely focus on the lowest bid. Consider the value proposition, factoring in factors like quality, service, lead time, and the supplier’s reputation.

Ready to take the next step? Contact Cozydoor today for a personalized consultation. Our team of experts will guide you through the selection process, helping you find the perfect aluminum extrusion profiles for your construction project.

Unlocking the Secrets of Aluminum Ore: What is Bauxite?

Cozydoor, your trusted partner in construction materials, is here to [...]

Nov

7 Ways Aluminum Uses in Industry

Aluminum has become a cornerstone material across various industries, thanks [...]

Nov

Understanding 6061 T6 Aluminum: Key Features Explained

Are you a construction project manager seeking a robust, versatile, [...]

Nov

7 Secrets of Structural Aluminum: Slash Costs & Boost Project Success

As a director or project manager in industrial construction, you’re [...]

Nov

7 Proven Ways Aluminum Foil Material Elevates Your Projects

This comprehensive guide unveils seven ways aluminum foil material can [...]

Nov

What Happens Inside an Aluminum Refinery? Find Out!

This comprehensive guide will walk you through the fascinating world [...]

Nov

Mastering the Conductivity of Al for Optimal Project Success

One key factor often overlooked is the strategic selection of [...]

Nov

What is the Modulus of Aluminium? Easy Explanation Here!

This seemingly technical term holds the key to unlocking the [...]

Nov