Aluminum’s remarkable properties have revolutionized industries, and its impact on modern construction is undeniable. This comprehensive guide delves deep into the world of aluminum, answering the fundamental question, “Is aluminum a metal?” and exploring its diverse applications, advantages, and sustainability within the construction sector.

From towering skyscrapers to sprawling warehouses, aluminum’s versatility offers innovative solutions for project managers and directors seeking efficiency, durability, and aesthetic appeal. Connect with Cozydoor today to unlock exclusive pricing and expert consultation tailored to your project’s needs.

Is Aluminum a Metal? Confirming Aluminum’s Metallic Nature

Yes, aluminum is definitively a metal. It resides within the periodic table as a post-transition metal, proudly displaying the symbol “Al” and atomic number 13. But what sets metals apart from other elements? Metals are characterized by their unique properties, including excellent electrical and thermal conductivity, malleability (the ability to be shaped without breaking), and ductility (the ability to be drawn into wires).

Aluminum embodies these characteristics, making it a versatile material with applications spanning numerous industries, especially construction. Its lightweight nature, combined with surprising strength, makes it ideal for structural components, facades, roofing, and more. For project managers navigating the complexities of modern construction, understanding these fundamental characteristics of aluminum is paramount.

What Defines a Metal?

Metals, like aluminum (aluminum element symbol: Al), are a distinct class of elements characterized by their unique atomic structure. This structure gives rise to the characteristic metallic bonding, where electrons are delocalized and free to move throughout the material.

This mobility of electrons is the reason why metals are such good conductors of both electricity and heat. The metallic bond also contributes to the malleability and ductility of metals, allowing them to be shaped and deformed without fracturing. These properties make metals, including aluminum, essential materials in various applications, from construction to electronics.

Aluminum’s Place in the Periodic Table (periodic table aluminum, aluminium element)

Located in Group 13 of the periodic table, aluminum is classified as a post-transition metal. Its position signifies its properties, which lie somewhere between the highly reactive metals of the alkali and alkaline earth groups and the more diverse transition metals. This strategic placement underscores its balanced nature – strong yet lightweight, reactive y etprotected by a durable oxide layer.

Understanding aluminum’s place within the periodic table provides insights into its behavior and interactions with other elements, crucial knowledge for construction professionals seeking to maximize its potential. This also clarifies that aluminum is indeed an element (is aluminum an element or compound, is aluminum a compound) and not a compound or a mixture (is aluminum a compound element or mixture).

Furthermore, it is not a mineral in its pure form (is aluminum a mineral, alu mineral, is aluminium a mineral), although it is widely extracted from the bauxite ore.

Understanding Aluminum’s Properties (Properties, properties of aluminum)

Aluminum’s unique combination of properties makes it an invaluable material in modern construction. Its remarkably low density, approximately one-third that of steel, significantly reduces structural weight, leading to cost savings in foundations and supporting frameworks.

This lightweight nature also simplifies transportation and installation, improving overall project efficiency. Furthermore, aluminum’s inherent corrosion resistance, thanks to a naturally forming protective oxide layer, minimizes maintenance requirements and extends the lifespan of structures.

This characteristic is particularly advantageous in challenging environments where other metals might succumb to rust and degradation.

Physical Properties of Aluminum

Aluminum’s silvery-white appearance, combined with its low density of 2.7 g/cm³, makes it aesthetically pleasing and structurally efficient. Its relatively low melting point (660.32 °C) allows for easy casting and shaping, while its high boiling point (2470 °C) ensures stability at elevated temperatures.

These properties, alongside its excellent thermal conductivity, contribute to aluminum’s versatility in construction applications, ranging from exterior cladding to interior fixtures.

Chemical Properties of Aluminum (chemical symbol of aluminum)

Aluminum, represented by the chemical symbol Al (aluminum element symbol, aluminium element symbol, periodic table symbol for aluminum), is highly reactive, readily forming a protective oxide layer upon exposure to air.

This passive oxide layer prevents further corrosion, making aluminum remarkably resistant to weathering and various chemical environments.

This inherent corrosion resistance is a critical factor in the longevity and durability of aluminum structures, significantly reducing maintenance costs and extending their lifespan.

Knowing this property is vital for construction professionals aiming for sustainable and resilient building designs. This also indicates that aluminum isn’t classified as a mineral but as an element (is aluminum a mineral, is aluminium a mineral). It’s not a compound either (is aluminum a compound).

Strength and Lightweight Characteristics (is aluminium malleable)

The remarkable combination of strength and lightness in aluminum makes it a preferred material for numerous construction applications. Despite its low density, aluminum alloys can achieve impressive strength-to-weight ratios, rivaling even some steel grades.

This characteristic allows for the creation of lightweight yet robust structures, offering significant advantages in terms of reduced material usage, transportation costs, and foundation requirements. For project managers seeking to optimize structural efficiency without compromising safety, aluminum’s strength-to-weight ratio is a crucial consideration.

Read more Blog & New:

Exploring the Diverse Uses of Aluminum

Aluminum’s versatility shines through its wide range of applications within the construction industry. From soaring curtain walls and roofing systems to intricate window frames and interior finishes, aluminum’s adaptability allows architects and engineers to create visually stunning and structurally sound buildings.

Its lightweight nature simplifies installation, reducing construction time and labor costs. Furthermore, its corrosion resistance ensures long-lasting performance, minimizing maintenance requirements and extending the lifespan of structures. Cozydoor provides premium aluminum solutions tailored to the specific needs of construction projects, ensuring quality, durability, and aesthetic appeal.

Aluminum in Construction and Infrastructure (what is aluminum used for)

Aluminum’s structural properties make it an ideal material for various construction applications. Its use in curtain walls provides a modern aesthetic and allows for large expanses of glass, maximizing natural light.

Aluminum roofing systems offer durability and weather resistance, while its lightweight nature simplifies installation and reduces the load on the building’s framework. In infrastructure projects, aluminum’s strength and corrosion resistance are invaluable in bridge construction and other demanding applications.

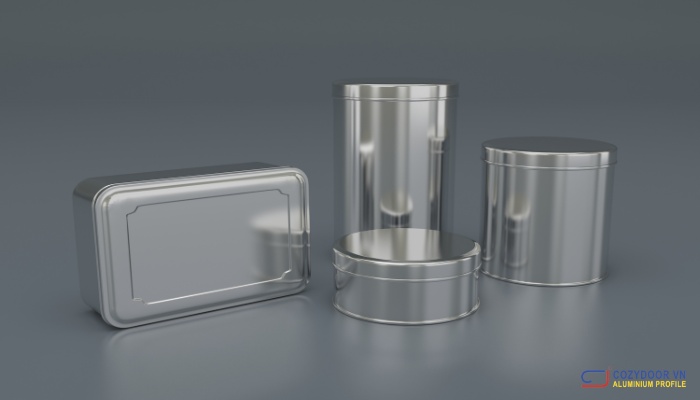

Aluminum in Packaging

While not directly related to structural construction, understanding aluminum’s role in packaging offers insights into its formability and protective qualities. Aluminum foil and cans demonstrate the metal’s malleability and ability to create airtight seals, protecting contents from moisture and oxygen.

This knowledge can be relevant for construction professionals considering aluminum’s applications in protective cladding or specialized enclosures.

Aluminum in Transportation

Aluminum’s lightweight nature is crucial in the transportation sector, improving fuel efficiency in vehicles. This knowledge can inform construction professionals about the potential benefits of using aluminum in prefabricated modular structures, reducing transportation costs and on-site assembly time.

Aluminum in Electrical Applications

Aluminum’s excellent electrical conductivity makes it a key material in power transmission lines. This understanding can be valuable for construction projects involving electrical systems and wiring, highlighting aluminum’s potential for efficient and safe electrical installations.

By now, the advantages of utilizing aluminum in construction should be evident. Its unique properties translate directly into cost savings, improved project timelines, and enhanced structural performance. Choosing Cozydoor as your aluminum supplier guarantees access to premium materials and expert guidance, ensuring your project’s success.

Aluminum Production and its Source (Bauxite, Electrolysis)

Aluminum is derived from bauxite ore, a reddish-brown rock found in various regions worldwide. The extraction process involves two main stages: refining bauxite into alumina (aluminum oxide) using the Bayer process, and then extracting pure aluminum from alumina through electrolysis.

This latter process, known as the Hall-Héroult process, is energy-intensive but essential for obtaining pure aluminum suitable for construction and other applications.

From Bauxite to Alumina

The Bayer process, developed in the late 19th century, effectively separates alumina from bauxite ore. This process involves crushing and grinding the bauxite, then dissolving it in a hot sodium hydroxide solution. The alumina dissolves, leaving behind impurities that are then filtered out. The resulting solution is cooled, and aluminum hydroxide precipitates out.

Finally, heating the aluminum hydroxide yields alumina, ready for the next stage of aluminum production.

The Electrolysis Process

Electrolysis is the key to obtaining pure aluminum from alumina. This process involves dissolving alumina in molten cryolite and then passing a powerful electric current through the mixture. The current breaks down the alumina, releasing pure aluminum, which settles at the bottom of the electrolytic cell.

This energy-intensive process is crucial for obtaining the high-purity aluminum required for various applications, including construction.

Environmental Considerations in Aluminum Production

Aluminum production requires significant energy input, primarily in the electrolysis stage. However, the industry is actively pursuing sustainable practices, including using renewable energy sources and improving energy efficiency.

Furthermore, aluminum’s high recyclability significantly reduces its environmental footprint, making it a more sustainable choice compared to other construction materials.

Comparing Aluminum to Closely Related Metals (Magnesium, Zinc, Copper)

Understanding how aluminum compares to other metals commonly used in construction, such as magnesium, zinc, and copper, can inform material selection decisions. While each metal offers specific advantages, aluminum often strikes the optimal balance between weight, strength, corrosion resistance, and cost-effectiveness.

Aluminum vs Magnesium

Magnesium, while lighter than aluminum, is generally less strong and more susceptible to corrosion. While magnesium alloys find applications in specialized areas, aluminum remains the preferred choice for many structural applications due to its superior overall performance.

Aluminum vs Zinc

Zinc is primarily used as a coating for steel to prevent corrosion (galvanization), while aluminum’s inherent corrosion resistance often eliminates the need for such coatings. In applications where lightweighting and inherent corrosion resistance are paramount, aluminum presents a distinct advantage.

Aluminum vs Copper

Copper, known for its excellent electrical conductivity, is often used in wiring and electrical systems. While aluminum’s conductivity is slightly lower than copper’s, its lower density and cost-effectiveness often make it the preferable choice for large-scale electrical applications, such as power transmission lines.

In construction, both metals have their specific applications, and the choice depends on the specific project requirements.

The Importance of Aluminum Recycling

Aluminum’s remarkable recyclability is a key factor in its sustainability. Recycling aluminum requires only a fraction of the energy needed to produce it from bauxite, significantly reducing greenhouse gas emissions and conserving natural resources.

The Aluminum Recycling Process

Recycling aluminum is a straightforward process. Collected aluminum scrap is melted down and then recast into new products, with minimal loss of material quality. This closed-loop recycling process can be repeated indefinitely, making aluminum a truly sustainable material.

Benefits of Aluminum Recycling

Recycling aluminum conserves energy, reduces landfill waste, and decreases the demand for bauxite mining. These environmental benefits align with the growing focus on sustainable construction practices, making recycled aluminum an increasingly attractive option for environmentally conscious project managers.

The Circular Economy of Aluminum

The concept of a circular economy emphasizes minimizing waste and maximizing resource utilization. Aluminum fits perfectly within this framework, thanks to its exceptional recyclability. By choosing aluminum and supporting recycling initiatives, the construction industry can contribute to a more sustainable future.

Ready to build smarter and more sustainably? Contact Cozydoor today for a free consultation. Our expert team can provide tailored solutions and preferential pricing for your next industrial construction project. Let us help you unlock the full potential of aluminum and achieve your project goals while minimizing your environmental impact. Fill out the form below to receive personalized assistance and exclusive offers.

7 Proven Ways Aluminum Foil Material Elevates Your Projects

This comprehensive guide unveils seven ways aluminum foil material can [...]

Nov

Discover the Different Types of Aluminum and Their Uses

The right aluminum can elevate your construction to new heights, [...]

Nov

10 Amazing Things Made by Aluminium You Didn’t Know About

Imagine sleek, modern structures rising against the skyline – lightweight [...]

Nov

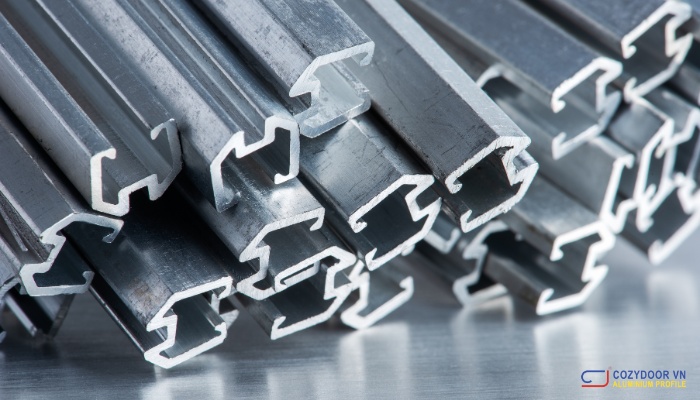

The Power of Aluminum Extrusion Profiles in Construction

Tired of the same old construction materials? Want to elevate [...]

Nov

5 Types of Anodizing to Elevate Your Construction Projects

Understanding the Different Types of Anodizing Anodizing is an electrochemical [...]

Nov

Mastering Aluminum Heat Transfer in Industrial Construction

Project managers and directors, imagine a world where temperature control [...]

Nov

What is the Modulus of Aluminium? Easy Explanation Here!

This seemingly technical term holds the key to unlocking the [...]

Nov

Top 5 Benefits of Aluminum Casting You Should Know

Are you a construction project manager seeking to revolutionize your [...]

Nov