Are you tired of project delays and budget overruns? Discover how extruded aluminum can revolutionize your industrial construction projects. This comprehensive guide unveils the secrets to choosing the right materials, optimizing designs, and ensuring long-lasting, stunning results. Claim your free consultation today!

What is Extruded Aluminum?

Extruded aluminum refers to aluminum that has been transformed into specific shapes through a process called extrusion. This method involves forcing heated aluminum billets through a die, creating long sections of aluminum with a uniform cross-sectional profile. The versatility of extruded aluminum makes it an ideal choice for various applications in industrial construction, such as factories, warehouses, and shopping centers.

The extrusion process allows for the production of complex shapes that can be tailored to meet specific design requirements. This adaptability is crucial for project managers and directors in industrial construction who seek materials that not only fulfill structural needs but also enhance aesthetic appeal. The lightweight yet durable nature of extruded aluminum contributes to its popularity in construction projects, providing a balance between strength and ease of handling.

Additionally, extruded aluminum is known for its excellent corrosion resistance, which extends the lifespan of structures and reduces maintenance costs. The ability to anodize or powder coat extruded profiles further enhances their durability and aesthetic qualities, making them suitable for both functional and decorative applications. As the demand for sustainable building materials grows, extruded aluminum stands out due to its recyclability and energy efficiency during production.

In summary, extruded aluminum is a versatile material that meets the technical and design requirements of modern construction projects while ensuring durability and aesthetic appeal.

The Extrusion Process: A Step-by-Step Explanation

The extrusion process for aluminum involves several key steps that ensure precision and quality in the final product:

- Billet Preparation: The process begins with the selection of aluminum billets, which are cylindrical pieces of aluminum alloy heated to a specific temperature (around 400-500°C) to make them malleable.

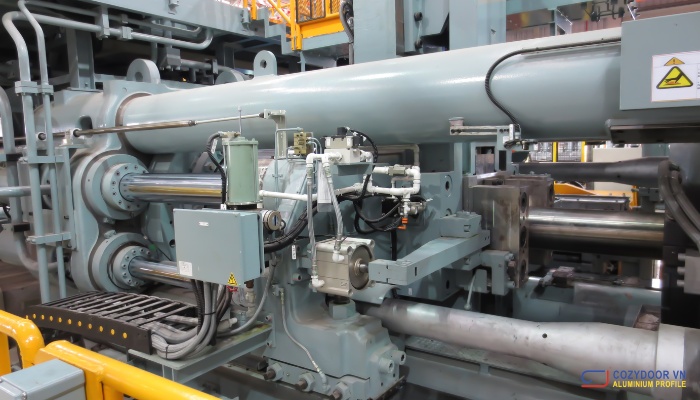

- Extrusion: The heated billet is placed in an extrusion press where it is forced through a die using a hydraulic ram. This action shapes the aluminum into the desired profile.

- Cooling: Once extruded, the aluminum profile is cooled using air or water to solidify its shape. This cooling process is crucial for maintaining dimensional accuracy.

- Cutting: After cooling, the long lengths of extruded aluminum are cut into manageable sections based on customer specifications.

- Finishing: The extruded profiles may undergo additional processes such as anodizing or powder coating to enhance surface properties and aesthetics.

- Quality Control: Throughout the extrusion process, quality control measures are implemented to ensure that the profiles meet industry standards and customer requirements.

This systematic approach ensures that manufacturers can produce high-quality extruded aluminum products efficiently while minimizing waste and optimizing costs.

Key Advantages of Extruded Aluminum

Extruded aluminum offers numerous advantages that make it an attractive choice for construction projects:

- Lightweight: Aluminum’s low density allows for easier handling and transportation without compromising structural integrity.

- Strength: Despite its lightweight nature, extruded aluminum exhibits high tensile strength, making it suitable for load-bearing applications.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents corrosion, extending the lifespan of structures.

- Versatility: The extrusion process allows for the creation of complex shapes tailored to specific design needs.

- Aesthetic Appeal: Extruded profiles can be anodized or powder-coated in various colors and finishes, enhancing visual appeal.

- Sustainability: Aluminum is highly recyclable, contributing to environmentally friendly construction practices.

These benefits position extruded aluminum as a preferred material among directors and project managers seeking reliable solutions for their construction needs.

Common Alloys Used in Extrusion

Different aluminum alloys are used in the extrusion process, each offering unique properties suited for various applications:

- 6061 Alloy: Known for its excellent mechanical properties and weldability, this alloy is commonly used in structural applications.

- 6063 Alloy: Often used for architectural applications due to its good surface finish and medium strength.

- 6082 Alloy: Offers high strength and good corrosion resistance, making it suitable for heavy-duty applications.

- 7005 Alloy: Known for its high strength-to-weight ratio, this alloy is often used in bicycle frames and sporting goods.

Understanding these alloys helps project managers select the appropriate material based on specific project requirements.

Exploring the Versatility of Aluminum Profiles

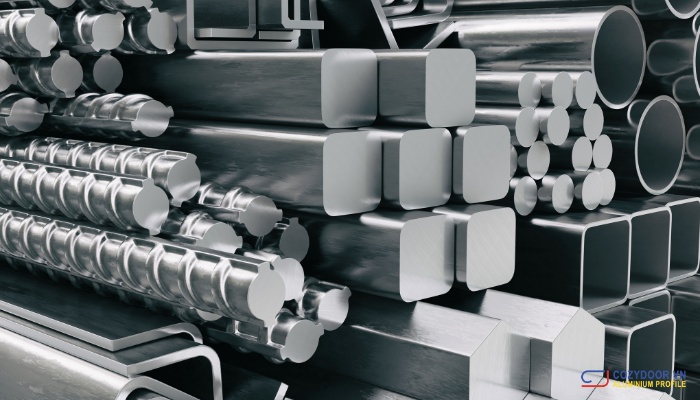

Aluminum profiles come in various shapes and sizes, allowing them to be utilized across multiple industries:

Standard Extruded Aluminum Shapes

Standard shapes include:

- T-Slots: Commonly used in framing systems and modular designs.

- Channels: Used in structural applications where load-bearing capabilities are required.

- Angles: Ideal for brackets and supports in construction.

These standard shapes provide flexibility in design while ensuring structural integrity.

Custom Profile Design and Manufacturing

Custom extrusions allow manufacturers to create unique profiles tailored to specific project needs. This capability enables directors and project managers to optimize designs while reducing material waste.

Applications of Extruded Aluminum Profiles in Various Industries

Extruded aluminum finds applications across diverse sectors:

- Construction: Used in window frames, doors, and structural components.

- Automotive: Employed in lightweight vehicle structures to improve fuel efficiency.

- Aerospace: Utilized for aircraft components due to its strength-to-weight ratio.

These applications highlight the adaptability of extruded aluminum across different fields.

Read more Blog & New:

Comparing Extruded Aluminum with Close Entities

Understanding how extruded aluminum compares with other forms of aluminum products helps project managers make informed decisions:

Extruded Aluminum vs. Aluminum Sheet

| Feature | Extruded Aluminum | Aluminum Sheet |

| Shape | Complex profiles | Flat sheets |

| Strength | High tensile strength | Moderate strength |

| Applications | Structural components | Cladding, roofing |

Extruded Aluminum vs. Aluminum Bar

| Feature | Extruded Aluminum | Aluminum Bar |

| Shape | Custom profiles | Rectangular bars |

| Fabrication | More complex | Simpler machining |

| Weight | Lighter | Heavier |

Extruded Aluminum vs. Aluminum Tube

| Feature | Extruded Aluminum | Aluminum Tube |

| Shape | Various profiles | Hollow cylindrical |

| Strength | Higher due to shape | Good but varies |

| Uses | Structural & decorative | Piping & tubing |

Choosing the Right Aluminum Product for Your Needs

When selecting between these options, consider factors such as application requirements, weight constraints, and cost-effectiveness.

Understanding Aluminum Alloys and Their Properties

Aluminum alloys play a crucial role in determining the properties of extrusions:

Common Aluminum Alloys for Extrusion

Common alloys include 6061, 6063, 6082, and 7005 as previously discussed. Each alloy offers distinct advantages depending on application needs.

Mechanical Properties of Different Aluminum Alloys

Understanding mechanical properties such as yield strength, tensile strength, and elongation helps project managers choose the right alloy based on load-bearing requirements.

Corrosion Resistance and Other Important Properties

Aluminum’s natural corrosion resistance makes it ideal for outdoor applications where exposure to elements is a concern. Additionally, its non-toxic nature ensures safety in various environments.

Working with Extruded Aluminum

Working effectively with extruded aluminum requires understanding various fabrication techniques:

Cutting and Machining Extruded Aluminum

Utilize saws or CNC machines designed specifically for cutting aluminum profiles accurately without damaging them.

Bending and Forming Extruded Aluminum

Bending can be achieved using specialized equipment that applies even pressure along the profile length to prevent cracking or deformation.

Joining Extruded Aluminum Profiles

Common joining methods include welding, riveting, or using mechanical fasteners depending on structural requirements.

Surface Finishing Options for Extruded Aluminum

Finishing options such as anodizing or powder coating enhance both durability and appearance while providing additional corrosion resistance.

By following these guidelines on working with extruded aluminum, directors and project managers can ensure efficient use of materials while optimizing costs. To explore more about how Cozydoor can assist you with your next project involving extruded aluminum materials—ensuring competitive pricing while meeting your deadlines—please fill out our contact form below! We look forward to providing you with expert consultation tailored to your specific needs!

10 Amazing Things Made by Aluminium You Didn’t Know About

Imagine sleek, modern structures rising against the skyline – lightweight [...]

Nov

Discover the Different Types of Aluminum and Their Uses

The right aluminum can elevate your construction to new heights, [...]

Nov

Understanding Steel Sheet Metal Gauge Charts Made Easy

The steel sheet metal gauge chart holds the key to [...]

Nov

Aircraft Grade Aluminum: Strong, Lightweight, and Reliable

In the competitive landscape of industrial construction, selecting the right [...]

Nov

Common Aluminum Grades: What You Need to Know

In the world of industrial construction, selecting the right materials [...]

Nov

7 Secrets to Mastering Aluminum Alloy in Industrial Construction

Are you tired of budget overruns and project delays? Discover [...]

Nov

The Power of Aluminum Extrusion Profiles in Construction

Tired of the same old construction materials? Want to elevate [...]

Nov

Aluminum Beverage Cans: A Surprisingly Powerful Resource

Tired of costly materials and construction delays? Imagine harnessing the [...]

Nov