Tired of the same old, cookie-cutter solutions for your industrial construction projects? Imagine having access to a world of possibilities with custom aluminum extrusions – designed to fit your exact specifications and optimize every aspect of your buildings. Cozydoor, a leading manufacturer of aluminum extrusions, is ready to empower you with innovative solutions that will:

Ready to discover how custom aluminum extrusions can revolutionize your next project?

Understanding Custom Aluminum Extrusions

Imagine the power of crafting architectural elements, structural supports, or even intricate machine parts with precision-engineered aluminum profiles. This is the essence of custom aluminum extrusions – a process that offers unparalleled flexibility and control over the design and functionality of your building materials.

What are Aluminum Extrusions?

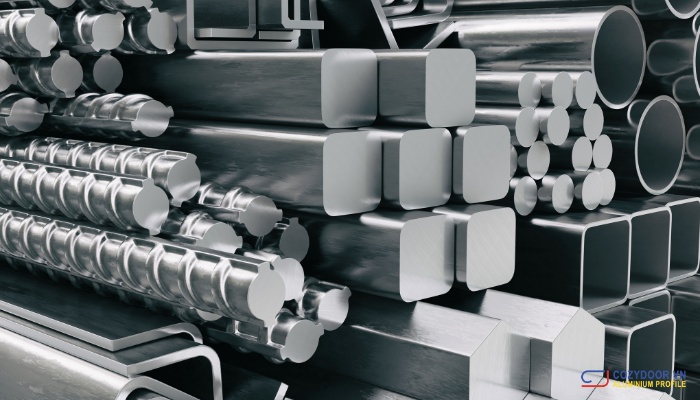

Aluminum extrusions are created by forcing heated aluminum through a precisely shaped die. This process, known as hot extrusion, generates complex profiles with consistent dimensional accuracy. Unlike other metal fabrication methods, aluminum extrusion offers exceptional flexibility in creating intricate shapes, hollow sections, and custom designs. This makes it an ideal choice for numerous industrial construction applications.

The Benefits of Choosing Custom Aluminum Extrusions

Custom aluminum extrusions offer numerous benefits over traditional building materials, making them an intelligent choice for discerning project managers like you.

- Design Flexibility and Tailored Solutions: Custom aluminum extrusions allow you to craft precisely shaped profiles that perfectly match your project’s unique requirements. This level of flexibility eliminates the need for costly on-site modifications and ensures a seamless integration with your design vision.

- Enhanced Functionality and Performance: Engineered to meet your specific needs, custom aluminum extrusions can significantly improve the functionality and performance of your building. From providing robust structural support to optimizing ventilation and thermal insulation, these specialized profiles offer a wide range of advantages.

- Improved Aesthetics and Branding Opportunities: Custom aluminum extrusions elevate the aesthetics of your building, creating visually stunning and unique architectural details. This can enhance your brand image and elevate the overall impression of your project.

- Cost Savings and Optimization: Custom aluminum extrusions can reduce overall material costs by eliminating waste and minimizing the need for secondary fabrication. This translates to cost-effective solutions without compromising on quality or performance.

- Increased Efficiency and Speed: Custom aluminum extrusions streamline your construction process, facilitating faster and more efficient installation compared to traditional materials. This allows you to meet project deadlines without compromising on quality.

- Enhanced Sustainability and Durability: Aluminum is a highly durable and recyclable material, making custom aluminum extrusions a sustainable and environmentally responsible choice for your projects. This reduces waste and promotes a greener footprint for your construction endeavors.

Common Aluminum Alloys Used in Extrusions

Choosing the right aluminum alloy is crucial for ensuring the strength, durability, and performance of your custom aluminum extrusions. The most common alloys used in construction applications include:

| Alloy | Characteristics | Common Applications |

| 6061 | Excellent strength, weldability, and corrosion resistance; highly versatile. | Structural framing, window frames, railing systems, automotive components |

| 6063 | Excellent formability and corrosion resistance; used for architectural applications. | Window frames, handrails, decorative elements, exterior cladding |

| 6005A | Higher strength than 6063, suitable for high-stress applications. | Truck frames, heavy-duty construction, transportation components |

| 7075 | Extremely high strength, ideal for demanding applications. | Aerospace components, aircraft frames, high-performance machinery |

How Custom Aluminum Extrusions Are Made

The process of creating custom aluminum extrusions involves careful planning and precise execution, using sophisticated equipment and expertise.

- Design and Engineering: Your design team collaborates closely with experienced engineers to create detailed specifications for your custom aluminum profiles. This involves carefully considering factors such as strength, weight, dimensions, and desired functionality.

- Die Fabrication: A specialized die is crafted based on the exact specifications of your custom aluminum extrusion. This die acts as a mold, shaping the heated aluminum into the desired profile.

- Extrusion Process: The heated aluminum billet is fed into the extrusion press, where it is forced through the die under extreme pressure. The process creates a continuous, shaped profile known as the extrusion.

- Finishing and Inspection: The extruded profile undergoes finishing processes such as cutting, machining, and surface treatment. Rigorous quality control ensures that the final product meets all specifications and industry standards.

Read more Blog & New:

Finding the Right Supplier for Your Custom Aluminum Extrusion Projects

Choosing the right supplier is crucial for ensuring the success of your project. Cozydoor’s expertise in manufacturing custom aluminum extrusions can provide you with the confidence and support you need to make informed decisions.

Key Factors to Consider When Choosing a Supplier

- Experience and Expertise: Look for an aluminum extrusion company with a proven track record of delivering high-quality custom solutions. Cozydoor’s team of engineers and technicians possesses decades of experience, ensuring you receive expert guidance every step of the way.

- Production Capabilities and Technology: Choose a supplier with advanced manufacturing capabilities that can meet your specific requirements. Cozydoor utilizes state-of-the-art extrusion presses and technology to deliver accurate, consistent, and reliable custom aluminum extrusions.

- Customer Service and Support: Partner with a company known for its responsiveness and commitment to customer satisfaction. Cozydoor provides dedicated support throughout your project, from initial design consultations to timely production and delivery.

Requesting Quotes and Comparing Prices

When requesting quotes from aluminum extrusion companies, consider factors such as:

- Material Costs: The price of aluminum varies based on alloy type, market conditions, and order volume.

- Production Costs: Production costs are influenced by the complexity of the extrusion profile, the required tooling, and the overall production volume.

- Delivery Costs: Consider transportation costs and potential shipping fees when comparing quotes from different suppliers.

- Lead Times: Understand the expected production timeframe and delivery schedule to ensure it aligns with your project timeline.

Understanding Lead Times and Production Capabilities

- Lead Times: Lead times for custom aluminum extrusions can vary depending on factors such as the complexity of the extrusion, the availability of the required alloy, and the current workload of the manufacturer.

- Production Capabilities: Select a supplier with production capabilities that match your project requirements. Cozydoor has the capacity to handle large-scale orders while maintaining consistent quality and on-time delivery.

Verifying Quality Certifications and Standards

- Quality Certifications: Ensure that the aluminum extrusion company you choose has the necessary certifications to meet industry standards.

- Compliance with Regulations: Confirm that the supplier adheres to relevant regulations and standards, such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) standards.

Exploring Applications of Custom Aluminum Extrusions Across Industries

Custom aluminum extrusions find versatile applications across diverse industries, offering innovative solutions that enhance safety, efficiency, and sustainability.

Architectural Applications

Custom aluminum extrusions revolutionize architectural design, offering a wide range of possibilities to create stunning and functional building elements.

- Facades and Curtain Walls: Custom aluminum extrusions enable the creation of aesthetically pleasing and energy-efficient facades and curtain walls. These systems can be designed to incorporate various glazing options, sunshades, and ventilation systems.

- Window Frames and Doors: Custom aluminum extrusions offer exceptional durability and strength, making them ideal for crafting high-performance windows and doors.

- Railing Systems and Handrails: Custom aluminum extrusions provide a combination of strength, durability, and sleek aesthetics for railing systems and handrails, enhancing safety and visual appeal in commercial and industrial spaces.

- Interior Design Elements: Custom aluminum extrusions can add a touch of sophistication and elegance to interior spaces, from intricate ceiling grids to decorative trim and moldings.

Automotive Applications

- Chassis and Frames: Custom aluminum extrusions provide lightweight yet durable structures for vehicle chassis and frames, enhancing fuel efficiency and handling performance.

- Body Panels: Aluminum extrusions are widely used for creating lightweight and aesthetically pleasing body panels, contributing to reduced weight and improved fuel efficiency.

- Engine Components: Custom aluminum extrusions play a vital role in manufacturing engine components, offering excellent heat dissipation and durability in demanding environments.

Industrial Applications

- Structural Support Systems: Custom aluminum extrusions provide robust and lightweight support systems for industrial buildings, warehouses, and manufacturing facilities.

- Conveyor Systems and Automation Equipment: These versatile profiles are used to design and fabricate conveyor systems, robotic arms, and other automated machinery, enhancing efficiency and productivity in industrial settings.

- Machinery Components: Custom aluminum extrusions contribute to the creation of durable and precision-engineered components for a wide range of industrial machinery.

Aerospace Applications

- Aircraft Structures: Custom aluminum extrusions are essential for constructing lightweight and durable aircraft structures, maximizing fuel efficiency and performance.

- Satellite and Spacecraft Components: Aluminum extrusions are utilized in spacecraft and satellite construction, providing high-strength and reliable components for demanding space environments.

Sustainability in Custom Aluminum Extrusion

Beyond their exceptional performance, custom aluminum extrusions offer significant advantages in terms of sustainability and environmental impact.

Sustainable Practices in Aluminum Extrusion Manufacturing

Cozydoor is committed to sustainable manufacturing practices, contributing to a greener future for the construction industry.

- Energy Efficiency: We employ energy-efficient manufacturing processes to minimize our carbon footprint and reduce energy consumption.

- Waste Reduction: We strive for minimal waste generation through optimized production techniques and recycling programs.

- Recycling and Reuse: Aluminum is highly recyclable, making it a circular material that can be reused numerous times without compromising its properties.

Recycling and Environmental Impact of Aluminum

Aluminum is a highly recyclable material, reducing the need for mining new resources and lowering environmental impact.

- Recyclability: Aluminum can be recycled infinitely without losing its properties.

- Reduced Carbon Footprint: Recycling aluminum requires significantly less energy than manufacturing it from raw materials, contributing to a lower carbon footprint.

- Responsible Sourcing: Cozydoor is committed to sourcing aluminum from suppliers who prioritize responsible mining practices and sustainable production methods.

Ready to experience the transformative power of custom aluminum extrusions?

Contact Cozydoor today for a personalized consultation!

Fill out the form below to receive expert advice and preferential pricing on your next custom aluminum extrusion project.

Let Cozydoor help you build a brighter future with precision-engineered solutions that will exceed your expectations.

Feel the Strength of Magnitude 7 Metals in Action

As a project manager, you understand the responsibility of building [...]

Nov

10 Amazing Things Made by Aluminium You Didn’t Know About

Imagine sleek, modern structures rising against the skyline – lightweight [...]

Nov

Understanding 6061 T6 Aluminum: Key Features Explained

Are you a construction project manager seeking a robust, versatile, [...]

Nov

The Ultimate Guide to Aluminum Extrusion Dies

This comprehensive guide will equip you with the knowledge and [...]

Nov

How Aluminum Rolling Works: A Quick Overview for All

From sprawling factories and warehouses to modern shopping centers, aluminum’s [...]

Nov

Understanding the Environmental Impact of Aluminum Production

As a director or project manager in industrial construction, you’re [...]

Nov

Aluminum Screen Rooms: Enjoy Nature Without Bugs

One innovative application gaining traction is the aluminum screen room [...]

Nov

5 Reasons Why Aluminum Sheet is the Smart Choice

Imagine a material that blends strength with lightness, resists corrosion, [...]

Nov