From sprawling factories and warehouses to modern shopping centers, aluminum’s lightweight nature, corrosion resistance, and design versatility make it the ideal choice for ambitious projects. This comprehensive guide, brought to you by Cozydoor, delves into the intricacies of aluminum rolling, providing you with actionable strategies to revolutionize your construction endeavors.

The Aluminum Rolling Process

Introduction to Metal Forming

Aluminum rolling is a pivotal metal-forming process that transforms aluminum slabs into usable forms for various applications, ranging from construction materials to packaging. As the demand for lightweight and durable materials continues to grow, understanding the aluminum rolling process becomes essential for directors and project managers in industrial construction.

This process not only enhances the material’s properties but also plays a crucial role in optimizing costs and ensuring timely project completion.

The rolling process involves several stages, including heating, rolling, and cooling, which together modify the aluminum’s microstructure. By employing techniques like hot and cold rolling, manufacturers can achieve specific thicknesses and mechanical properties tailored to meet industry standards.

For construction projects, this means sourcing high-quality rolled aluminum that meets both technical specifications and aesthetic requirements.

The Aluminum Rolling Process in Detail

The aluminum rolling process can be broken down into three primary steps:

- Aluminum Stock Preparation: Initially, aluminum slabs or billets are prepared for rolling. Depending on the desired properties, the stock may be heated (hot rolling) or processed at room temperature (cold rolling). Hot rolling is generally preferred for achieving significant reductions in thickness without compromising ductility.

- Rolling to Desired Thickness: The prepared aluminum undergoes several passes through roller mills, where it is subjected to immense pressure that reduces its thickness. The final product can be categorized as either plate (thicker than 0.25 inches), sheet (0.2 to 0.25 inches), or foil (less than 0.006 inches). Each category serves different applications within the construction industry.

- Further Processing: After achieving the desired thickness, rolled aluminum products may undergo additional processing such as cutting or surface treatments to enhance durability and aesthetics. Treatments like anodization improve corrosion resistance, making aluminum suitable for various environmental conditions.

Key Process Parameters and Their Effects

Understanding the key parameters of the aluminum rolling process is essential for optimizing production efficiency and material quality:

- Temperature Control: The temperature at which aluminum is rolled significantly affects its mechanical properties. Hot rolling typically occurs at temperatures between 260°C to 510°C (500°F to 950°F), allowing for easier deformation and improved ductility.

- Rolling Speed: The speed of the rolling mill impacts productivity and material quality. Higher speeds can lead to increased production rates but may also introduce defects if not properly managed.

- Thickness Reduction Ratio: This ratio determines how much the material’s thickness is reduced during each pass through the mill. A higher reduction ratio often results in improved mechanical properties but requires careful monitoring to avoid excessive strain on the material.

Read more Blog & New:

Exploring Different Aluminum Alloys and Their Applications

Common Aluminum Alloys for Rolling

Aluminum alloys are categorized based on their primary alloying elements, which significantly influence their properties:

- 1000 Series: Known for excellent corrosion resistance and high thermal conductivity, these alloys are often used in electrical applications.

- 2000 Series: These alloys are known for their high strength-to-weight ratio, making them ideal for aerospace applications.

- 3000 Series: Commonly used in packaging and cooking utensils due to their excellent workability and moderate strength.

- 5000 Series: These alloys offer good corrosion resistance and are widely used in marine environments.

- 6000 Series: Known for their versatility, these alloys are often used in structural applications due to their good weldability.

Material Properties and Their Influence

The choice of alloy directly influences the performance of the final product in construction applications. For example:

- Strength: Higher strength alloys are preferred for structural components in buildings.

- Corrosion Resistance: Alloys with enhanced corrosion resistance are essential for outdoor applications.

- Workability: Alloys that are easier to work with can reduce manufacturing costs and improve production efficiency.

Application-Specific Alloy Selection

Selecting the right alloy for a specific application involves considering factors such as load-bearing requirements, environmental conditions, and aesthetic preferences. For instance:

- Architectural Applications: Alloys with excellent surface finishes are preferred for visible structures like facades.

- Structural Components: High-strength alloys are necessary for load-bearing elements such as beams and columns.

Aluminum Sheet, Plate, and Coil: Product Forms and Specifications

Defining Sheet, Plate, and Coil

Aluminum products come in various forms:

- Sheet: Thin pieces of rolled aluminum typically used in applications requiring lightweight yet strong materials.

- Plate: Thicker than sheets, plates are used where additional strength is required.

- Coil: Rolled sheets that can be further processed into various shapes or products.

Standard Sizes, Thicknesses, and Tolerances

Understanding standard sizes and tolerances is crucial when sourcing aluminum materials:

| Product Form | Thickness Range | Standard Sizes |

| Sheet | 0.2 mm – 6 mm | 4′ x 8′, 5′ x 10′ |

| Plate | >6 mm | Custom sizes available |

| Coil | Varies | Customizable based on application |

Surface Finishes and Treatments

Surface treatments enhance both aesthetics and functionality:

- Anodization: Increases corrosion resistance while allowing for color finishes.

- PVDF Coating: Provides a durable finish suitable for architectural applications.

Finding the Right Aluminum Rolling Mill and Equipment

Types of Rolling Mills

Different types of rolling mills cater to various production needs:

- Hot Rolling Mills: Used primarily for thick slabs; ideal for large-scale production.

- Cold Rolling Mills: Suitable for producing thinner gauges with tighter tolerances.

- Tandem Mills: Allow continuous processing through multiple stands for efficiency.

Selecting the Right Rolling Mill

Choosing a rolling mill depends on factors such as:

- Production volume requirements

- Desired product specifications

- Budget constraints

Ancillary Equipment for Rolling Mills

Incorporating ancillary equipment can enhance efficiency:

- Annealing Furnaces: Used between passes to maintain material ductility.

- Cooling Systems: Essential for managing temperature during processing.

Quality Control and Assurance in Aluminum Rolling

Industry Standards and Certifications

Adhering to industry standards ensures product quality:

- ISO 9001 Certification

- ASTM Standards

- EN Standards

Inspection Techniques and Methods

Implementing rigorous inspection techniques helps maintain quality throughout production:

- Visual Inspections

- Non-destructive Testing (NDT)

- Dimensional Checks

To ensure your projects benefit from high-quality aluminum materials that meet technical specifications while optimizing costs, consider partnering with reliable suppliers like Cozydoor. Fill out your contact information today to receive personalized consultations and preferential pricing tailored to your needs!

Aluminium Coloring Made Simple: Step-by-Step Instructions

Aluminium is a highly versatile material widely used in industrial [...]

Nov

7 Secrets to Mastering Aluminum Alloy in Industrial Construction

Are you tired of budget overruns and project delays? Discover [...]

Nov

Aluminum Beverage Cans: A Surprisingly Powerful Resource

Tired of costly materials and construction delays? Imagine harnessing the [...]

Nov

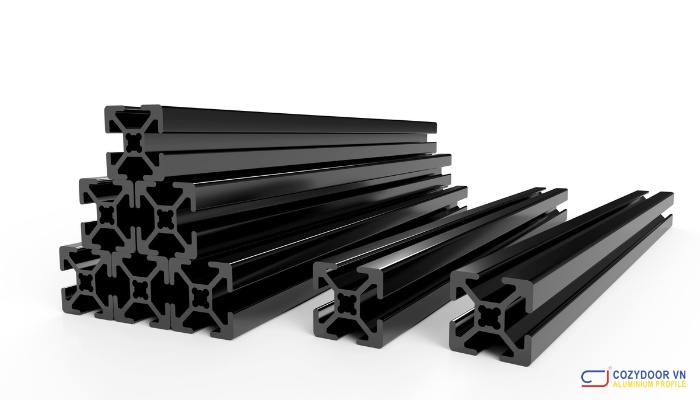

Custom Aluminum Extrusions: Perfect Fit for Your Design Needs

Tired of the same old, cookie-cutter solutions for your industrial [...]

Nov

Aluminum Screen Rooms: Enjoy Nature Without Bugs

One innovative application gaining traction is the aluminum screen room [...]

Nov

The Ultimate Guide to Aluminum Extrusion Dies

This comprehensive guide will equip you with the knowledge and [...]

Nov

Mastering Aluminum Heat Transfer in Industrial Construction

Project managers and directors, imagine a world where temperature control [...]

Nov

Understanding Steel Sheet Metal Gauge Charts Made Easy

The steel sheet metal gauge chart holds the key to [...]

Nov