Cozydoor, a leading provider of high-quality aluminum plate materials, understands the challenges you face. We’ve worked with countless construction professionals like you, providing the knowledge, expertise, and top-notch aluminum plate solutions that help you deliver projects on time and within budget. Our mission is to be your trusted partner, ensuring your projects are successful from start to finish.

Understanding Aluminum Plate Properties and Uses

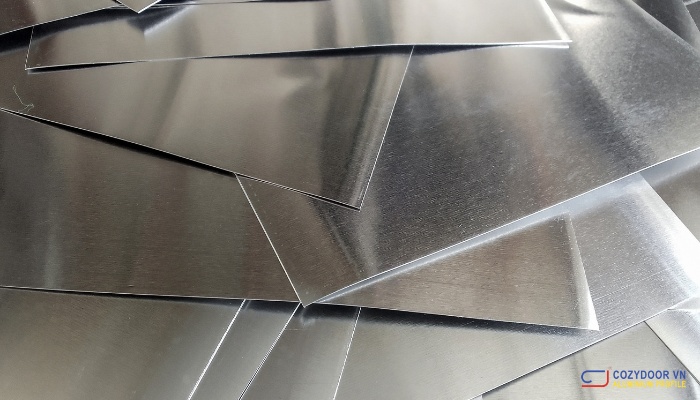

Aluminum plate is a versatile material with exceptional properties that make it an ideal choice for a wide range of construction projects. Its strength, durability, and lightweight nature set it apart from traditional materials like steel, while its corrosion resistance and recyclability make it a sustainable option for modern construction.

What Defines Aluminum Plate?

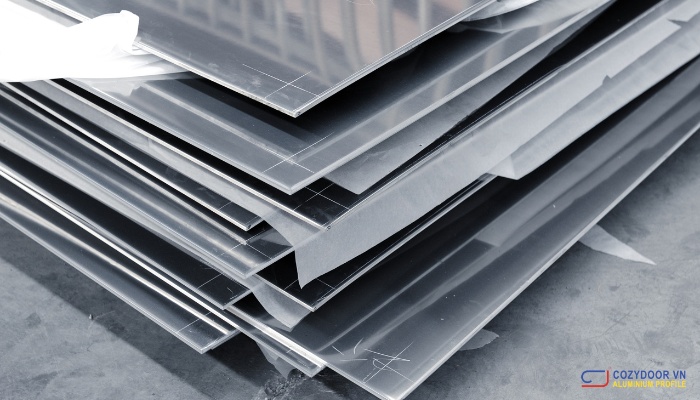

Aluminum plate, often referred to as aluminium metal plate, is a flat, sheet-like material made from aluminum. It’s distinguished from other forms of aluminum, like aluminum sheet, which is typically thinner and more flexible, and aluminum panel, which might include composite materials or coatings. Aluminum plate is known for its strength, making it suitable for structural applications where a solid, sturdy material is needed.

Exploring the Core Properties of Aluminum Plate

Lightweight and Durable: Imagine the benefits of using a material that is incredibly strong yet lightweight. This is the magic of aluminium plate. Its low density allows for easier handling and transportation, while its high strength ensures structural integrity and stability.

Exceptional Corrosion Resistance: Aluminum naturally forms a protective oxide layer that acts as a shield against corrosion. This means your aluminum plate structures will withstand the harsh elements and maintain their integrity for years to come, minimizing maintenance and replacement costs.

Malleable and Easy to Work With: Unlike rigid materials that require specialized machinery, aluminium plate can be shaped, cut, and fabricated easily. This versatility allows for greater design flexibility and the creation of intricate structures with precision.

Excellent Thermal and Electrical Conductivity: Aluminium plate is an excellent conductor of heat and electricity, making it ideal for various applications where these properties are crucial, such as heat sinks or electrical grounding.

Applications of Aluminum Plate Across Industries

Aluminium plate is a powerhouse of versatility, finding its way into a vast array of construction projects, from industrial structures to commercial buildings.

Industrial Construction:

- Factory Buildings: Aluminum plate is perfect for building robust walls, roofs, and structural supports that can withstand the heavy machinery and demanding environments found in factories.

- Warehouses: Its strength and corrosion resistance make aluminium plate an excellent choice for warehouse construction, where durability and longevity are paramount.

- Industrial Platforms: Aluminium plate forms the backbone of elevated work platforms and walkways, providing safe and stable working surfaces.

Commercial Construction:

- Shopping Centers: Aluminum plate’s sleek aesthetic and durability make it a favorite for creating eye-catching facades and modern architectural features.

- Office Buildings: Its lightweight nature and corrosion resistance make aluminium plate a cost-effective and long-lasting material for constructing building exteriors.

- Retail Stores: Aluminum plate offers a blend of strength and visual appeal, making it ideal for creating structural supports, signage, and decorative elements.

Other Applications:

- Automotive: Aluminium plate is a common material in vehicle manufacturing, used for body panels, engine components, and other structural parts.

- Marine: Its corrosion resistance makes aluminum plate ideal for building boats, marine structures, and other applications exposed to harsh marine environments.

- Aerospace: Aluminum plate plays a crucial role in aircraft manufacturing, where its lightweight yet strong properties are essential.

Why Choose Aluminum Plate Over Other Materials?

Aluminium plate offers a compelling combination of advantages that surpass traditional materials in many construction scenarios.

- Cost-Effective: While initial costs may seem higher than some materials, aluminum plate’s durability and longevity translate to lower long-term costs. Its lightweight nature reduces transportation and labor costs, further adding to its cost-effectiveness.

- Environmentally Sustainable: Aluminum is a highly recyclable material, making it a sustainable choice for environmentally conscious construction projects. Its production process also has a lower environmental impact compared to some other metals.

- Enhanced Safety: Aluminium plate’s strength and stability contribute to safer working environments, reducing the risk of collapses or accidents. Its fire-resistant properties also enhance building safety.

- Aesthetic Appeal: Aluminum plate can be finished in various ways, offering a wide range of aesthetic options to complement any architectural style. It can be polished for a sleek, modern look, or left with a brushed or textured finish for a more industrial feel.

Exploring Different Aluminum Plate Alloys and Thicknesses

Aluminum plate comes in a wide variety of alloys and thicknesses, each tailored to specific construction needs. Understanding these options is crucial for optimizing your projects and ensuring the best performance.

Common Aluminum Alloys Used in Plate Production

Aluminum alloys are created by adding other elements like magnesium, copper, silicon, or manganese to pure aluminum. These alloying elements enhance specific properties, making the aluminum plate suitable for particular applications.

- 6061 Aluminum: Known for its excellent strength, corrosion resistance, and weldability, 6061 aluminium plate is a popular choice for structural applications in various industries.

- 5052 Aluminum: This alloy offers good corrosion resistance and formability, making it ideal for applications where bending or shaping is required.

- 3003 Aluminum: Known for its workability and corrosion resistance, 3003 aluminium plate is a cost-effective option for non-structural applications.

- 1100 Aluminum: This soft and highly malleable alloy is often used for decorative purposes or applications where a high degree of formability is required.

Understanding Aluminium Plate Thickness Specifications

Aluminium plate thickness is typically measured in millimeters (mm) or inches (in). Choosing the correct thickness depends on the intended use, load-bearing requirements, and structural design.

- Thin Aluminium Plate: Used for decorative elements, non-structural applications, or where lightweight construction is essential.

- Medium-Thickness Aluminum Plate: Suitable for structural applications, where a balance of strength and weight is necessary.

- Thick Aluminium Plate: Ideal for demanding structural applications, where high strength and load-bearing capacity are crucial.

Selecting the Optimal Alloy and Thickness for Your Needs

When choosing the right aluminum plate for your construction project, consider the following factors:

- Load-Bearing Requirements: Determine the weight and stresses the aluminium plate will need to support.

- Environmental Conditions: Consider factors like humidity, temperature variations, and exposure to corrosive elements.

- Aesthetic Considerations: Choose an alloy and finish that meet your aesthetic requirements for the project.

- Budgetary Constraints: Balance performance and aesthetics with budget limitations.

Read more Blog & New:

Working with Aluminum Plate

Aluminum plate is versatile and can be easily manipulated with the right tools and techniques. This section explores methods for cutting, shaping, and finishing aluminium plate.

Effective Methods for Cutting Aluminum Plate

Cutting aluminum plate requires specialized tools and techniques to achieve clean, precise cuts.

- Plasma Cutting: A high-temperature plasma torch melts and cuts through the aluminium plate, creating a clean cut.

- Waterjet Cutting: This method uses a high-pressure stream of water to cut through the aluminum plate with minimal heat and distortion.

- Laser Cutting: A laser beam cuts through the aluminium plate with extreme precision, allowing for intricate designs.

- Saw Cutting: While not as precise as plasma or waterjet cutting, saws can be used for basic cutting tasks.

Techniques for Shaping and Bending Aluminium Plate

Aluminium plate is malleable and can be shaped and bent using various techniques.

- Bending: Aluminum plate can be bent using brakes, rollers, or hand-bending tools.

- Rolling: Aluminum plate can be rolled into desired shapes using specialized rolling machines.

- Forming: Aluminum plate can be formed into complex shapes using various forming techniques, such as stamping, pressing, or drawing.

Achieving Different Surface Finishes on Aluminum Plate

Aluminum plate can be finished in various ways to achieve desired aesthetics and properties.

- Mill Finish: The standard finish, with a slightly rough texture, is cost-effective and suitable for many applications.

- Anodizing: A process that creates a hard, protective oxide layer on the aluminum surface, enhancing corrosion resistance and providing a variety of colors.

- Powder Coating: A durable and decorative coating that can be applied in various colors and textures.

- Polishing: Creating a smooth, reflective finish, often used for decorative purposes.

The Sustainability of Aluminium Plate

Aluminium plate is an environmentally responsible choice, contributing to sustainable construction practices.

The Role of Recycling in the Aluminum Plate Lifecycle

Aluminum is a highly recyclable material, making it a sustainable option for construction projects. Recycling aluminum requires significantly less energy than producing new aluminum, reducing the environmental impact.

Sustainable Practices in the Aluminium Industry

The aluminium industry is constantly innovating to minimize environmental impact.

- Recycling Initiatives: Companies are investing in advanced recycling technologies and programs to promote the recycling of aluminum.

- Energy Efficiency: The industry is adopting energy-efficient manufacturing processes to reduce energy consumption and emissions.

- Green Manufacturing: Companies are using sustainable practices and materials throughout the manufacturing process.

Cozydoor is committed to providing high-quality aluminum plate materials that meet the needs of demanding construction projects. Our team of experts is dedicated to helping you achieve your construction goals with efficiency and confidence.

For a personalized consultation and to receive preferential prices, please fill out the contact form below. Our team will be happy to answer your questions and help you select the perfect aluminum plate solution for your project needs.

5 Types of Anodizing to Elevate Your Construction Projects

Understanding the Different Types of Anodizing Anodizing is an electrochemical [...]

Nov

7 Secrets to Mastering Aluminum Alloy in Industrial Construction

Are you tired of budget overruns and project delays? Discover [...]

Nov

Raw Ingot Aluminum Cannery: A Comprehensive Guide

Cozydoor, your trusted partner in construction, understands the complexities of [...]

Nov

The Major Aluminum Producers You Should Know About

This comprehensive guide will equip you with the insights you [...]

Nov

Unlocking the Secrets of Aluminum Ore: What is Bauxite?

Cozydoor, your trusted partner in construction materials, is here to [...]

Nov

A380 Aluminum Properties: 5 Ways to Slash Costs & Boost Project Timelines

Cozydoor recognizes the demands of your industry and is committed [...]

Nov

Mastering Extruded Aluminum in Industrial Construction

Are you tired of project delays and budget overruns? Discover [...]

Nov

Aluminium Coloring Made Simple: Step-by-Step Instructions

Aluminium is a highly versatile material widely used in industrial [...]

Nov