Project managers and directors, imagine a world where temperature control in your industrial builds isn’t a constant battle, where energy efficiency is maximized, and material costs are optimized. Aluminum’s exceptional heat transfer properties can make this a reality.

At Cozydoor, we understand the pressures of delivering high-quality projects on time and within budget. This comprehensive guide unveils the power of aluminum heat transfer and how it can revolutionize your approach to industrial construction, from factories and warehouses to sprawling shopping centers.

The Fundamentals of Heat Transfer

Understanding the principles of heat transfer is crucial for professionals in industrial construction, particularly when selecting materials that optimize efficiency, safety, and cost. Heat transfer refers to the movement of thermal energy from one object or medium to another, which can occur through three primary modes: conduction, convection, and radiation. Each mode plays a significant role in how materials like aluminum are utilized in construction and manufacturing processes.

The Three Modes of Heat Transfer

- Conduction: This is the transfer of heat through direct contact between materials. Metals, including aluminum, are excellent conductors due to their free electrons, which facilitate energy transfer.

- Convection: This involves the movement of heat through fluids (liquids or gases). In industrial applications, convection is often enhanced by fans or pumps to improve heat dissipation.

- Radiation: Unlike conduction and convection, radiation does not require a medium; it transfers heat through electromagnetic waves. While less relevant for solid materials like aluminum, it still plays a role in overall thermal management strategies.

The Significance of Thermal Conductivity in Heat Transfer

Thermal conductivity is a material’s ability to conduct heat. For aluminum, this property is particularly advantageous; its thermal conductivity ranges from 205 to 235 W/(m·K), making it one of the best conductors among metals after copper. This high thermal conductivity allows for effective heat dissipation in applications such as heat exchangers and cooling systems.

Temperature Gradients and Their Influence

Temperature gradients also significantly influence thermal conductivity. As temperature increases, the kinetic energy of atoms rises, which can enhance or inhibit conductivity depending on the material’s structure and phase. Understanding these gradients enables engineers to design systems that maintain optimal operational temperatures.

Aluminum: The Ideal Metal for Heat Transfer Applications

Aluminum stands out as a preferred material for various heat transfer applications due to its unique properties that enhance performance while reducing costs.

The High Thermal Conductivity of Aluminum

Aluminum’s superior thermal conductivity makes it an ideal choice for applications requiring efficient heat management. Its ability to quickly absorb and dissipate heat ensures that machinery operates within safe temperature ranges, thus improving reliability and longevity.

Aluminum Alloys and Their Varying Thermal Properties

Different aluminum alloys exhibit varying thermal properties based on their composition. For instance, alloys such as 6061 and 7075 are commonly used in construction and automotive applications due to their balance of strength and thermal performance. Understanding these variations allows project managers to select the most suitable alloy for specific applications.

Aluminum vs Copper: A Comparative Analysis for Heat Transfer

While copper has higher thermal conductivity than aluminum (approximately 400 W/(m·K)), aluminum offers advantages such as lower weight and cost-effectiveness. For many industrial applications, these benefits outweigh the slight decrease in thermal performance compared to copper.

Leveraging the Unique Characteristics of Aluminum

Aluminum’s lightweight nature combined with its excellent corrosion resistance makes it an attractive option for construction projects where both strength and durability are required. Its malleability allows for complex shapes that can enhance design aesthetics while maintaining functionality.

Optimizing Heat Transfer with Aluminum Heat Sinks

Heat sinks are critical components in managing excess heat in electronic devices and machinery. Optimizing their design can significantly enhance performance.

Key Design Considerations for Effective Heat Sinks

When designing aluminum heat sinks, consider factors such as surface area, airflow direction, and fin geometry. Increasing surface area improves heat dissipation rates, while proper airflow ensures that hot air is effectively removed from the component.

Different Types of Heat Sinks and Their Applications

- Passive Heat Sinks: Rely on natural convection; ideal for low-power applications.

- Active Heat Sinks: Use fans or pumps to enhance cooling; suitable for high-performance systems.

- Heat Pipes: Utilize phase change principles to transfer heat efficiently across distances.

Choosing the Right Heat Sink for Your Specific Needs

Selecting the appropriate heat sink involves analyzing the thermal load requirements of your application. Factors such as ambient temperature, space constraints, and noise levels should guide your decision-making process.

Read more Blog & New:

Effective Cooling Systems Utilizing Aluminum

Aluminum plays a vital role in various cooling systems across industries.

The Role of Aluminum in Heat Exchangers

Heat exchangers made from aluminum are essential in systems where efficient thermal transfer is necessary. Their lightweight nature facilitates easier installation and maintenance while providing excellent thermal performance.

Utilizing Aluminum Components in Liquid Cooling Systems

Liquid cooling systems benefit from aluminum’s properties by utilizing aluminum radiators and coolant channels that enhance heat transfer efficiency while minimizing weight.

Applications of Aluminum Cooling Solutions Across Industries

From automotive engines to HVAC systems, aluminum cooling solutions are integral in maintaining optimal operational temperatures across various sectors.

Exploring Advanced Cooling Techniques with Aluminum

Innovative techniques such as additively manufactured lattice structures present new opportunities for enhancing cooling efficiency by optimizing fluid dynamics within cooling systems.

Manufacturing Considerations for Aluminum Heat Transfer Components

The manufacturing process significantly impacts the performance characteristics of aluminum components used in heat transfer applications.

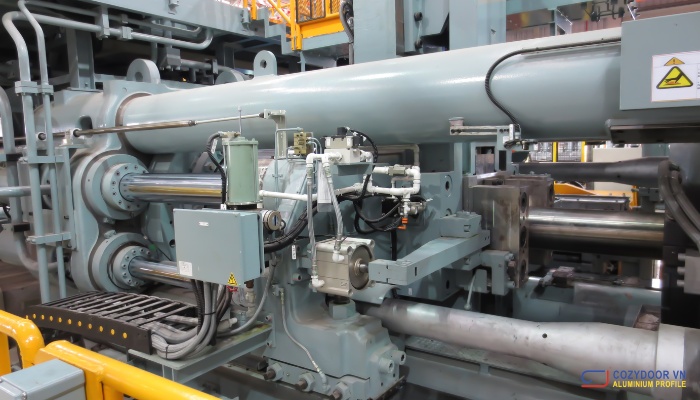

Aluminum Extrusion

Extrusion is a popular method used to create complex shapes that maximize surface area for enhanced heat transfer capabilities. This process allows manufacturers to produce tailored components that meet specific design requirements efficiently.

The Impact of Manufacturing Processes on Thermal Performance

Processes such as casting, forging, and additive manufacturing can alter the microstructure of aluminum alloys, affecting their thermal conductivity. Understanding these effects is crucial when designing components intended for high-performance applications.

The Importance of Recyclability and Sustainability in Aluminum Heat Transfer

Aluminum’s recyclability is a critical factor in its sustainability profile. Utilizing recycled aluminum not only reduces material costs but also minimizes environmental impact—a consideration increasingly important in today’s construction projects.

In conclusion, understanding aluminum heat transfer is essential for directors and project managers aiming to optimize designs while ensuring safety and efficiency in industrial construction projects.

By leveraging aluminum’s unique properties—such as its high thermal conductivity and lightweight nature—professionals can reduce material costs without compromising quality or performance.

For tailored advice on selecting the right aluminum materials for your projects at competitive prices while ensuring timely delivery, please fill out your contact information below to receive preferential pricing options from Cozydoor!

Discover the Different Types of Aluminum and Their Uses

The right aluminum can elevate your construction to new heights, [...]

Nov

Is Aluminum a Metal? Unlocking its Potential for Modern Construction

Aluminum’s remarkable properties have revolutionized industries, and its impact on [...]

Nov

Aluminium Coloring Made Simple: Step-by-Step Instructions

Aluminium is a highly versatile material widely used in industrial [...]

Nov

Explore the Benefits of Using Aluminum 7075 Today

In today’s fast-paced construction landscape, project managers face mounting pressure [...]

Nov

7 Proven Ways Aluminum Foil Material Elevates Your Projects

This comprehensive guide unveils seven ways aluminum foil material can [...]

Nov

Learn About the Types of Extruded Aluminum and Their Benefits

Are you a construction project manager constantly juggling tight deadlines, [...]

Nov

How is Aluminum Produced? Aluminum Production

Aluminum isn’t simply dug out of the ground like gold. [...]

Nov

Aluminum Extruded Products: Durable and Cost-Effective Choices

Cozydoor, a leading provider of aluminum extruded products, is here [...]

Nov