Cozydoor, a leading provider of aluminum extruded products, is here to empower your projects with the cutting-edge solutions you deserve. We’re not just suppliers; we’re your partners in achieving construction excellence.

Ready to unlock the potential of aluminum extruded products? Let’s dive into the world of this versatile material and discover how it can transform your next project.

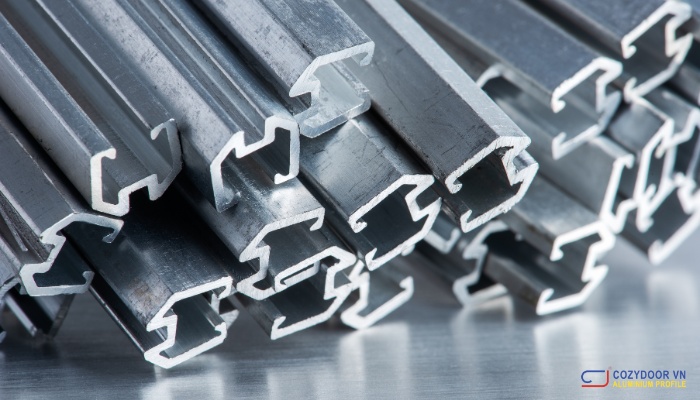

Aluminum Extruded Products and Their Applications

Aluminum extruded products have become an indispensable component in modern construction, offering a robust and adaptable solution for a wide range of applications.

Think beyond the ordinary. Aluminum extrusions are more than just building materials; they’re design elements that enhance functionality, durability, and aesthetics. They offer unparalleled flexibility in creating custom shapes and intricate profiles, exceeding the limitations of traditional materials.

Here’s a glimpse into the versatility of aluminum extruded products:

- Structural components: From window frames and door frames to roofing systems and curtain walls, aluminum extrusions provide strength and stability. They are ideal for supporting heavy loads and resisting harsh weather conditions.

- Industrial applications: Aluminum extrusions are widely used in factories, warehouses, and manufacturing facilities for everything from machinery parts to conveyor systems. They are known for their durability, resistance to wear and tear, and ease of maintenance.

- Retail spaces: In shopping centers, aluminum extruded products are commonly used for structural elements, storefront facades, and display fixtures. They offer a sleek and modern aesthetic, enhancing the visual appeal of any retail space.

What is Aluminum Extrusion?

Aluminum extrusion is a highly precise process that involves forcing a heated aluminum billet through a specifically designed die to create custom-shaped profiles. The process is renowned for its ability to produce intricate and complex cross-sections that would be impossible to achieve with traditional methods.

Think of it as a controlled squeezing process:

- A heated aluminum billet is pushed through a hardened steel die, carefully crafted to create the desired shape.

- The die’s shape determines the final profile of the extruded product.

- The result is a durable and precise aluminum profile that can be readily used for various applications.

Advantages of Using Aluminum Extruded Products

Aluminum extruded products offer a plethora of advantages, making them a top choice for construction projects:

- Lightweight and Strong: This combination is a game-changer for construction. Aluminum extrusions offer exceptional strength-to-weight ratio compared to steel, reducing structural loads and making them easier to handle and install.

- Corrosion Resistance: Aluminum naturally resists corrosion, making it ideal for outdoor applications and environments prone to moisture. This durability ensures long-lasting performance and minimizes maintenance requirements.

- Versatile Designs: The extrusion process allows for infinite design possibilities, enabling engineers and architects to create complex and customized profiles to meet specific project needs.

- Cost-Effectiveness: While initial costs may be slightly higher than traditional materials, the long-term benefits of aluminum extrusions, including durability and reduced maintenance, make them a cost-effective choice over the lifespan of your project.

Let’s delve deeper into the key features and benefits of aluminum extrusions.

Key Features and Benefits of Aluminum Extrusions

Strength-to-Weight Ratio

Imagine building structures that are lighter and stronger simultaneously. Aluminum extrusions achieve this remarkable feat, allowing you to maximize structural integrity while minimizing weight. This benefit translates into numerous advantages for your construction projects:

- Reduced Structural Loads: Lighter materials mean less strain on foundations and supporting structures, potentially leading to cost savings in the overall design and construction process.

- Simplified Installation: Lighter components are easier to handle, transport, and install, enhancing worker safety and speeding up the project timeline.

- Optimized Energy Efficiency: Lightweight structures require less energy to build and maintain, contributing to sustainability and reduced environmental impact.

Remember, strength isn’t solely determined by weight. Aluminum extrusions are engineered to withstand demanding conditions, providing exceptional performance and durability.

Corrosion Resistance

Aluminum’s natural resistance to corrosion is a significant advantage in construction, especially in outdoor and exposed environments. This inherent property translates into:

- Longer Lifespan: Aluminum extrusions are less susceptible to rust and deterioration, extending the lifespan of your structures and minimizing maintenance requirements.

- Reduced Maintenance Costs: Withstanding the elements means fewer repairs and replacements, saving you money in the long run.

- Enhanced Aesthetics: Aluminum extrusions maintain their appearance over time, preserving the visual integrity of your buildings and projects.

Consider this: In coastal areas or regions with high humidity, aluminum extrusions provide superior protection against corrosion, ensuring that your structures remain strong and visually appealing for years to come.

Customization Options

One of the most exciting features of aluminum extrusions is their remarkable customizability. The extrusion process allows engineers and architects to create unique shapes and profiles to meet specific project requirements. This unparalleled flexibility opens up a world of possibilities:

- Optimized Designs: Tailor-made profiles can enhance structural performance, improve functionality, and optimize aesthetics, resulting in a truly bespoke construction solution.

- Architectural Freedom: Aluminum extrusions allow for creative and innovative designs, pushing the boundaries of architectural expression and creating unique visual statements.

- Increased Functionality: Custom extrusions can be designed with integrated features and functionalities that streamline processes, improve user experience, and optimize performance.

Imagine creating intricate patterns, incorporating functional features, and achieving the perfect aesthetic for your project. Aluminum extrusions give you the power to bring your unique vision to life.

Read more Blog & New:

Industries Benefiting from Aluminum Extruded Products

The diverse applications of aluminum extruded products extend across numerous industries, making them a valuable resource for various sectors.

Automotive Industry Applications

- Lightweight Body Panels: Aluminum extrusions significantly reduce the weight of vehicles, improving fuel efficiency and handling.

- Structural Components: They are used in chassis components, suspension systems, and other structural elements, enhancing durability and safety.

- Interior Trim: Aluminum extrusions offer a modern and sophisticated aesthetic, adding a touch of elegance to vehicle interiors.

The automotive industry embraces aluminum extrusions for their lightweight properties, durability, and design flexibility.

Construction Sector Uses

- Window and Door Frames: Aluminum extrusions provide strength, energy efficiency, and a contemporary aesthetic for various window and door systems.

- Facade Systems: They are commonly used in curtain walls, cladding systems, and other exterior elements, providing structural support, weather resistance, and design flexibility.

- Roofing Systems: Aluminum extrusions offer durability, lightweight, and corrosion resistance for roofing systems, making them ideal for various climates and building types.

The construction sector leverages aluminum extrusions for their structural integrity, weather resistance, and adaptability to diverse design requirements.

Electronics and Electrical Applications

- Heatsinks: Aluminum extrusions offer excellent thermal conductivity, making them ideal for dissipating heat in electronic components and devices.

- Enclosures: They provide durability, shielding, and aesthetic appeal for electronic enclosures and housings.

- Electrical Conduits: Aluminum extrusions are used in electrical systems for conduits and wiring protection, offering durability and safety.

The electronics and electrical industry relies on aluminum extrusions for their thermal management properties, electrical conductivity, and durability.

Cozydoor’s expertise in aluminum extruded products ensures that your construction projects benefit from the exceptional qualities of this innovative material. Our team of experienced professionals is dedicated to providing high-quality products, competitive pricing, and expert advice.

Ready to transform your construction projects with aluminum extruded products? Contact Cozydoor today for a personalized consultation and discover the endless possibilities that this remarkable material offers.

Fill out the form below to receive a free consultation and exclusive access to preferential pricing.

How Is Aluminum Mined? A Simple Overview

Understanding “how is aluminum mined” is more than just a [...]

Nov

A380 Aluminum Properties: 5 Ways to Slash Costs & Boost Project Timelines

Cozydoor recognizes the demands of your industry and is committed [...]

Nov

How is Aluminum Produced? Aluminum Production

Aluminum isn’t simply dug out of the ground like gold. [...]

Nov

Discover the Different Types of Aluminum and Their Uses

The right aluminum can elevate your construction to new heights, [...]

Nov

Can You Recycle Aluminum? The Science Behind It Explained

In the ever-evolving landscape of construction, sustainability is no longer [...]

Nov

Discover the Different Aluminum Types You Need to Know

Are you tired of the same old materials? Ready to [...]

Nov

Aluminium Coloring Made Simple: Step-by-Step Instructions

Aluminium is a highly versatile material widely used in industrial [...]

Nov

5 Reasons Why Aluminum Sheet is the Smart Choice

Imagine a material that blends strength with lightness, resists corrosion, [...]

Nov