Imagine a material that blends strength with lightness, resists corrosion, and offers endless design possibilities. That’s the magic of aluminum sheet, a true game-changer in the world of construction.

Aluminum Sheet: Properties and Applications

Aluminum sheets are an essential material in various industries, particularly in construction, automotive, aerospace, and packaging. Their unique properties, including lightweight, corrosion resistance, and excellent thermal conductivity, make them ideal for a wide range of applications.

As project managers and directors in industrial construction, understanding the benefits and characteristics of aluminum sheets can significantly impact your projects’ efficiency and cost-effectiveness.

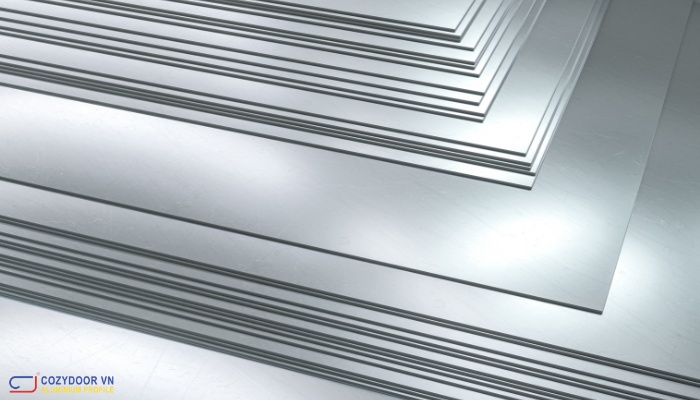

What is an Aluminum Sheet?

An aluminium sheet is a flat piece of aluminum that has been rolled or pressed into a thin layer. These sheets can vary in thickness, size, and alloy composition to meet specific application requirements. Aluminium sheets are available in various grades, each offering distinct properties suitable for different uses.

For instance, the 6061 aluminum sheet is known for its strength and versatility, making it a popular choice in structural applications.

Key Properties of Aluminium Sheet

Aluminum sheets possess several key properties that contribute to their widespread use:

- Lightweight: Aluminum is approximately one-third the weight of steel, allowing for easier handling and reduced transportation costs.

- Corrosion Resistance: The natural oxide layer on aluminum provides excellent resistance to corrosion, making it suitable for outdoor applications.

- Thermal Conductivity: Aluminum has high thermal conductivity, which is beneficial in applications requiring heat dissipation.

- Ductility: Aluminium sheets can be easily formed into complex shapes without cracking or breaking.

- Recyclability: Aluminum is 100% recyclable without loss of quality, contributing to sustainability efforts.

Common Aluminum Sheet Alloys

Different alloys offer varying properties tailored to specific applications:

- 6061 Alloy: Known for its excellent mechanical properties and corrosion resistance; commonly used in structural components.

- 5052 Alloy: Offers good weldability and formability; ideal for marine environments.

- 3003 Alloy: Known for its excellent workability; often used in cooking utensils and chemical equipment.

Diverse Applications of Aluminium Sheet

Aluminium sheets are utilized across numerous sectors due to their advantageous properties:

- Construction: Used for roofing, cladding, and building facades due to their lightweight and aesthetic appeal.

- Automotive: Employed in body panels and engine components because of their strength-to-weight ratio.

- Aerospace: Essential in aircraft structures where weight savings are critical.

- Packaging: Commonly used in food and beverage containers due to their corrosion resistance and recyclability.

Read more Blog & New:

Aluminum Sheet vs Close Entities

Understanding how aluminium sheets compare with other materials can help you make informed decisions for your projects.

Aluminum Sheet vs Steel Sheet

| Property | Aluminum Sheet | Steel Sheet |

| Weight | Lightweight | Heavier |

| Corrosion Resistance | Excellent | Moderate (requires coatings) |

| Strength | Good (varies by alloy) | High |

| Cost | Generally higher | Generally lower |

Aluminium sheets are preferred when weight savings are essential, while steel may be chosen for its superior strength.

Aluminum Sheet vs Copper Sheet

| Property | Aluminum Sheet | Copper Sheet |

| Weight | Lightweight | Heavier |

| Electrical Conductivity | Good | Excellent |

| Corrosion Resistance | Excellent | Moderate |

| Cost | Generally lower | Generally higher |

While copper offers superior electrical conductivity, aluminum is often favored for its lighter weight and cost-effectiveness.

Aluminum Sheet vs Plastic Sheet

| Property | Aluminum Sheet | Plastic Sheet |

| Durability | High | Variable |

| Weight | Lightweight | Lightweight |

| Environmental Impact | Recyclable | Often not recyclable |

| Cost | Generally higher | Generally lower |

Aluminum sheets provide greater durability compared to plastic sheets, making them suitable for more demanding applications.

Choosing the Right Sheet Metal for Your Project

When selecting materials for your construction projects, consider factors such as weight requirements, environmental exposure, aesthetic preferences, and budget constraints. Engaging with reliable suppliers like Cozydoor can help you find the right aluminium sheet that meets your technical specifications while optimizing costs.

Finding the Right Aluminium Sheet

Choosing the correct aluminum sheet involves understanding various factors that influence performance and cost.

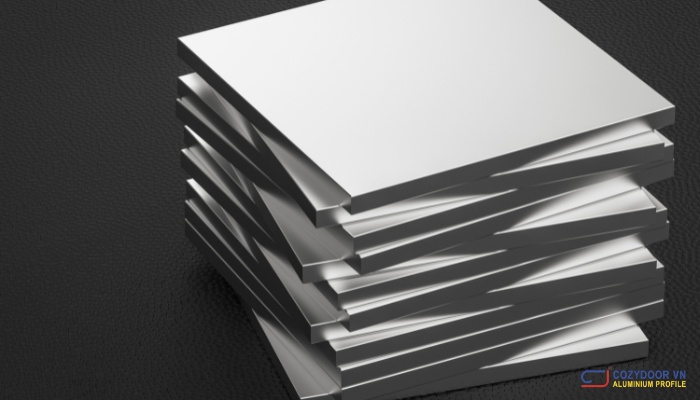

Understanding Aluminum Sheet Thickness and Gauge

Aluminum sheet thickness is measured in gauges; a lower gauge indicates a thicker sheet. Common gauges range from 0.016 inches (24 gauge) to 0.250 inches (1/4 inch). Selecting the appropriate thickness is crucial based on the application requirements—thicker sheets offer greater strength but may increase costs.

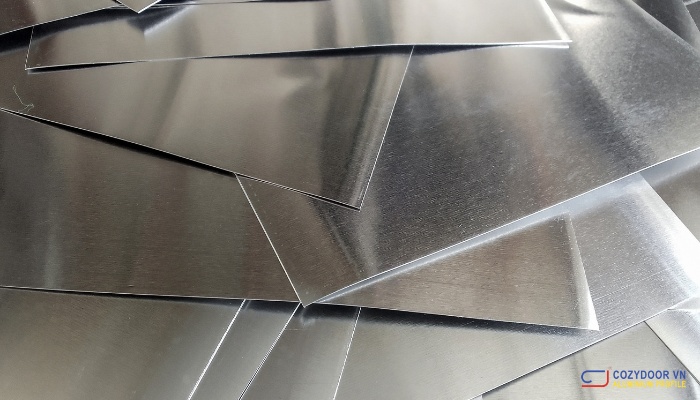

Different Finishes and Surface Treatments

The finish of an aluminium sheet can impact its appearance and performance:

- Anodized Finish: Enhances corrosion resistance and allows for color options.

- Painted Finish: Provides aesthetic appeal while protecting against environmental damage.

- Mill Finish: Raw surface with no additional treatment; suitable for industrial applications.

Standard and Custom Aluminum Sheet Sizes

Aluminium sheets come in standard sizes (e.g., 4×8 feet), but custom sizes can be ordered to fit specific project needs. Working with suppliers like Cozydoor ensures access to both standard and custom dimensions that align with your design specifications.

Working with Aluminum Sheet

To maximize the benefits of aluminium sheets in your projects, understanding fabrication techniques and best practices is essential.

Common Aluminum Sheet Fabrication Techniques

Several methods can be employed to fabricate aluminium sheets:

- Cutting: Using saws or lasers to achieve desired dimensions.

- Bending: Employing press brakes to create angles or curves.

- Welding: Joining pieces using MIG or TIG welding techniques for structural integrity.

- Stamping: Creating complex shapes through high-pressure stamping processes.

Best Practices for Handling and Storing Aluminum Sheet

Proper handling and storage are vital to maintaining the quality of aluminium sheets:

- Store sheets flat on a clean surface to prevent warping.

- Use protective coverings to shield from moisture and contaminants.

- Handle with care to avoid scratches or dents during transport.

The Importance of Aluminum Sheet Recycling

Recycling aluminium sheets offers significant environmental benefits. The recycling process consumes only about 5% of the energy required to produce new aluminum from ore. By choosing recycled aluminum materials whenever possible, you contribute to sustainability efforts while also reducing material costs.

In conclusion, understanding the properties, applications, and advantages of aluminium sheets can significantly enhance your project’s efficiency while optimizing costs.

For high-quality aluminum products that meet your construction deadlines without compromising on safety or aesthetics, consider partnering with Cozydoor. Fill out our contact form today to receive personalized advice and competitive pricing tailored to your project needs!

Milling Aluminum: A Step-by-Step Process Explained

Cozydoor understands that as a project manager or director, your [...]

Nov

Mastering Aluminum Heat Transfer in Industrial Construction

Project managers and directors, imagine a world where temperature control [...]

Nov

Feel the Strength of Magnitude 7 Metals in Action

As a project manager, you understand the responsibility of building [...]

Nov

5052 Aluminum vs 6061: The Ultimate Guide for Construction Pros

Unlock the secrets to building smarter, stronger, and more cost-effective [...]

Nov

Power of Aluminium Die Casting

Are you a construction professional looking to optimize your projects [...]

Nov

The Power of Aluminum Extrusion Profiles in Construction

Tired of the same old construction materials? Want to elevate [...]

Nov

When Was Aluminum Discovered? A Brief History

Why should you care about the history of aluminum? Understanding [...]

Nov

Understanding Steel Sheet Metal Gauge Charts Made Easy

The steel sheet metal gauge chart holds the key to [...]

Nov