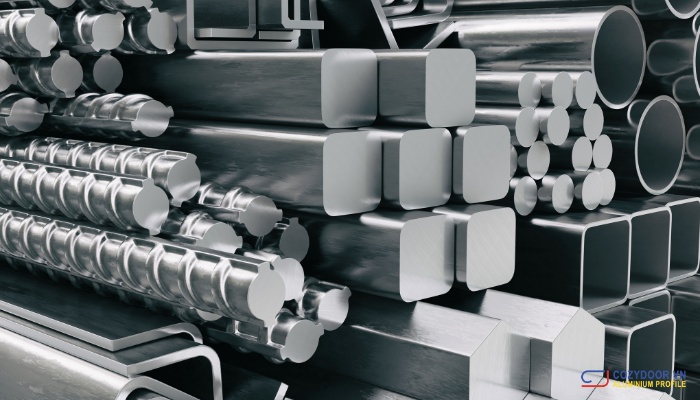

In the world of industrial construction, selecting the right materials is crucial for ensuring project success. Aluminium, known for its lightweight and corrosion-resistant properties, plays a vital role in various applications, from structural components to decorative finishes. This article delves into common aluminium grades, providing insights that will help directors and project managers optimize their material choices for better performance, cost efficiency, and safety.

Understanding Aluminum Grades and Their Properties

Imagine walking into a hardware store and being faced with an overwhelming array of aluminum sheets, bars, and profiles. Each with a unique label, a distinct color, and a cryptic series of numbers and letters.

This is the world of aluminum grades, and understanding their properties is essential for informed decision-making.

What Defines an Aluminum Grade?

The aluminum you see isn’t pure aluminum; it’s an alloy. These alloys are created by adding specific percentages of other metals like magnesium, silicon, copper, and manganese to pure aluminum.

Each alloying element brings unique properties to the table. Think of it like a recipe; the proportions of each ingredient determine the final flavor and texture of your dish.

The Aluminum Association (AA) Standard:

To ensure consistency and clarity across the industry, the Aluminum Association (AA) established a standardized system for classifying aluminum alloys. Each grade is assigned a unique four-digit number, followed by a letter representing its temper designation. This system simplifies communication and ensures that project teams worldwide can readily identify and understand the properties of specific aluminum grades.

Here’s an example:

- AA 6061-T6: This designation indicates a specific aluminum alloy, 6061, that has been heat-treated to achieve a specific temper, designated as T6.

Understanding the AA system is a vital first step in making confident decisions about aluminum grades.

Exploring Key Properties

Each aluminum grade possesses a unique combination of properties, influencing its performance in various applications. Here are some of the key properties you should consider:

- Strength: The ability of an aluminum grade to withstand forces without breaking or deforming. This property is crucial for structural applications, load-bearing components, and ensuring overall safety.

- Corrosion Resistance: Aluminum’s natural ability to resist oxidation and corrosion, protecting it from environmental degradation. This property is particularly important for projects exposed to harsh weather conditions.

- Workability: How easily an aluminum grade can be shaped, bent, or formed. This property is essential for intricate designs, complex profiles, and achieving specific aesthetic elements.

- Conductivity: Aluminum’s ability to conduct heat and electricity. This property is relevant for specific applications, such as heat sinks, electrical wiring, and HVAC systems.

How Chemical Composition Influences Performance

The composition of an aluminum alloy plays a significant role in shaping its properties. By adjusting the proportions of alloying elements, manufacturers can fine-tune the strength, ductility, corrosion resistance, and workability of the material.

Here’s an example:

- Magnesium: The addition of magnesium increases the strength of the aluminum alloy. This property is essential for demanding structural applications.

- Silicon: Silicon enhances the castability and machinability of aluminum, making it easier to create intricate shapes and complex components.

- Copper: Copper enhances the strength of aluminum at elevated temperatures, making it ideal for applications where heat resistance is crucial.

Decoding Temper Designations

The temper designation, a single letter following the alloy number, indicates the material’s physical condition. This condition is achieved through specific heat treatments and mechanical processes.

Here’s a breakdown of common temper designations:

- T6: This temper is achieved through a combination of heat treatment and artificial aging, resulting in a high level of strength and hardness.

- T4: This temper involves solution heat treatment followed by natural aging, leading to a moderate level of strength and good workability.

- T3: This temper involves solution heat treatment followed by cold working, resulting in a higher level of strength and improved workability.

Understanding the properties and characteristics of aluminum grades will help you confidently select the right one for your construction project. Now, let’s explore how these grades translate into real-world applications.

Read more Blog & New:

Selecting the Right Aluminum Grade for Your Application

The world of construction is as diverse as the buildings themselves, with countless projects demanding specific materials and properties. Aluminum, with its diverse range of grades, offers solutions for a wide variety of applications.

Aerospace Applications

The aerospace industry demands the highest standards of strength, lightweight construction, and corrosion resistance. Aluminum plays a vital role in aircraft construction, fulfilling these critical requirements.

Here are some popular aluminum grades for aerospace applications:

- AA 2024: Renowned for its exceptional strength-to-weight ratio, AA 2024 is used for fuselage and wing structures, where high-strength performance is paramount.

- AA 7075: This grade boasts excellent strength and toughness, making it ideal for critical components like landing gear, wing spars, and other load-bearing structures.

Automotive Applications

The automotive industry is constantly innovating, demanding materials that enhance performance and fuel efficiency. Aluminum’s lightweight nature and corrosion resistance make it a sought-after material in vehicle construction.

Here are some common aluminum grades used in automotive applications:

- AA 6061: This versatile grade offers a balance of strength, workability, and corrosion resistance, making it ideal for chassis components, wheels, and suspension parts.

- AA 5052: Known for its superior corrosion resistance, this grade is commonly used for body panels, trim components, and exterior applications that require enduring protection against the elements.

Construction Applications

Aluminum’s strength, durability, and workability make it an excellent choice for a wide range of construction applications, from commercial buildings to industrial facilities.

Here are some common aluminum grades used in construction projects:

- AA 5052: This grade offers a balance of strength, corrosion resistance, and workability, making it ideal for architectural cladding, curtain walls, and roofing systems.

- AA 6061: This versatile grade is often used for structural framing, window and door frames, and other load-bearing applications in commercial and industrial buildings.

3D Printing and Manufacturing

The rapid growth of 3D printing has opened up new possibilities for aluminum in construction, creating unique and complex geometries.

Here are some aluminum grades commonly used in 3D printing:

- AA 6061: This grade’s excellent machinability and strength make it suitable for 3D printed components with intricate designs and demanding performance requirements.

- AA 5052: This grade’s superior corrosion resistance and workability make it well-suited for 3D printing applications where durability and aesthetic appeal are paramount.

Balancing Cost and Availability

While selecting the right aluminum grade for your project, remember that cost and availability are crucial considerations.

- Price Fluctuations: The price of aluminum can fluctuate based on market demand, global events, and supply chain dynamics. It’s wise to research current market conditions and seek out suppliers who offer competitive pricing and reliable supply chains.

- Availability: Some aluminum grades are more readily available than others. Considering the time frame of your project, it’s crucial to ensure that the chosen grade is easily procured in sufficient quantities to meet your deadlines.

Understanding these factors will help you make informed decisions about aluminum grades, ensuring a smooth and cost-effective construction project.

Read more Blog & New:

Common Aluminum Grades: A Closer Look

Now, let’s dive deeper into the world of common aluminum grades, exploring their specific properties and applications to guide your selection process.

6061 Aluminum: A Versatile Choice

AA 6061 is a versatile workhorse, often regarded as the most popular aluminum grade for a wide range of construction applications.

Here’s why:

- Exceptional Strength and Workability: It offers a good balance of strength and workability, making it suitable for structural components, architectural elements, and complex shapes.

- Excellent Corrosion Resistance: Its natural resistance to corrosion ensures its longevity and durability in various environments.

- Good Machinability: 6061 aluminum is relatively easy to machine, making it suitable for precision components and intricate details.

Common Applications:

- Structural Framing: Window frames, door frames, beams, and columns in commercial and industrial buildings

- Architectural Cladding: Curtain walls, exterior panels, and decorative features

- Machined Components: Parts for machinery, equipment, and vehicles

- 3D Printing: Complex shapes, intricate designs, and prototypes

2024 Aluminum: Strength and Performance

AA 2024 is the epitome of high-strength aluminum, known for its exceptional performance in demanding applications.

Key Features:

- Exceptional Strength: This grade boasts the highest strength among common aluminum alloys, making it ideal for critical structural components and load-bearing applications.

- Good Fatigue Resistance: It excels in situations where repetitive stresses are present, ensuring long-term durability and structural integrity.

Typical Applications:

- Aircraft Structures: Fuselage, wings, and other high-stress components in aircraft construction

- Aerospace Components: Rocket bodies, satellite structures, and other demanding applications

- High-Performance Vehicles: Racing cars, motorsport components, and other applications requiring exceptional strength and durability

5052 Aluminum: Balancing Strength and Corrosion Resistance

AA 5052 is the go-to choice when corrosion resistance and workability are key priorities.

Key Features:

- Superior Corrosion Resistance: This grade offers excellent protection against oxidation and environmental degradation, making it ideal for exterior applications and marine environments.

- Good Strength and Workability: It strikes a balance between strength and ease of shaping, making it versatile for various construction and architectural applications.

Common Applications:

- Architectural Cladding: Exterior panels, curtain walls, and roofing systems for buildings exposed to harsh weather conditions

- Marine Applications: Boat hulls, marine hardware, and other applications exposed to seawater and salt spray

- Chemical and Industrial Equipment: Containers, tanks, and components that require resistance to corrosive chemicals

Exploring Other Common Grades

While these three grades represent the most frequently used in construction, other common grades offer unique advantages for specific applications:

- AA 7075: This high-strength aluminum grade, commonly used in aerospace applications, offers exceptional tensile strength and good fatigue resistance.

- AA 1100: This commercially pure aluminum grade, known for its excellent ductility and workability, is frequently used for decorative purposes and non-load-bearing applications.

Understanding the specific characteristics of these grades is crucial for making informed decisions. Now, let’s explore how aluminum compares to other materials commonly used in construction.

Comparing Aluminum to Close Entity Materials

When choosing the best material for your construction project, it’s essential to weigh the benefits of aluminum against those of other commonly used materials.

Aluminum vs Magnesium Alloys

Magnesium alloys are known for their exceptionally lightweight nature, even lighter than aluminum.

Here’s a comparison:

| Property | Aluminum | Magnesium |

| Weight | Lighter than steel, heavier than magnesium | The lightest structural metal |

| Strength | Good strength | Lower strength than aluminum |

| Corrosion Resistance | Excellent | Susceptible to corrosion |

| Cost | Moderate | More expensive than aluminum |

Aluminum offers a balance of strength and corrosion resistance, making it a more reliable choice for many construction applications.

Aluminum vs Copper Alloys

Copper alloys are known for their excellent conductivity and resistance to corrosion.

Here’s a comparison:

| Property | Aluminum | Copper Alloys |

| Conductivity | Good conductivity | Excellent conductivity |

| Corrosion Resistance | Excellent | Excellent in most environments |

| Cost | Moderate | More expensive than aluminum |

| Workability | Good workability | Less malleable than aluminum |

Aluminum offers a better balance of cost, workability, and corrosion resistance, making it a suitable choice for many construction applications.

Aluminum vs Titanium Alloys

Titanium alloys are renowned for their exceptional strength, corrosion resistance, and high-temperature performance.

Here’s a comparison:

| Property | Aluminum | Titanium Alloys |

| Strength | Good strength | Very high strength |

| Corrosion Resistance | Excellent | Excellent in most environments |

| Cost | Moderate | Significantly more expensive than aluminum |

| Weight | Lightweight | Heavier than aluminum |

While titanium offers superior strength and corrosion resistance, its high cost and weight make aluminum a more practical choice for most construction projects.

Choosing the right aluminum grade is a critical decision that can impact your project’s success. By understanding the properties of different grades, their suitability for specific applications, and the cost-effectiveness of each choice, you can confidently select the best material for your construction project.

Contact Cozydoor today to receive expert advice and preferential pricing on a wide range of aluminum products!

Fill out the form below to receive a free consultation and unlock the full potential of aluminum for your next construction project!

5052 Aluminum vs 6061: The Ultimate Guide for Construction Pros

Unlock the secrets to building smarter, stronger, and more cost-effective [...]

Nov

Aluminium Coloring Made Simple: Step-by-Step Instructions

Aluminium is a highly versatile material widely used in industrial [...]

Nov

How the Aluminum Recycling Process Can Save Your Project

As a director or project manager in industrial construction, you’re [...]

Nov

7 Secrets to Mastering Aluminum Alloy in Industrial Construction

Are you tired of budget overruns and project delays? Discover [...]

Nov

10 Amazing Things Made by Aluminium You Didn’t Know About

Imagine sleek, modern structures rising against the skyline – lightweight [...]

Nov

The Benefits of Using High Tensile Aluminium in Construction

In today’s fast-paced construction landscape, project managers and directors constantly [...]

Nov

Aluminum Extruded Products: Durable and Cost-Effective Choices

Cozydoor, a leading provider of aluminum extruded products, is here [...]

Nov

Power of Aluminium Die Casting

Are you a construction professional looking to optimize your projects [...]

Nov