Are you a construction project manager constantly juggling tight deadlines, budget constraints, and demanding design specifications? Imagine seamlessly integrating high-performance, lightweight materials that enhance both the structural integrity and aesthetic appeal of your projects. Discover the power of extruded aluminum—a versatile solution transforming the modern construction landscape. This comprehensive guide unveils the Types of Extruded Aluminum, empowering you to make informed decisions that elevate your projects to new heights of efficiency, durability, and visual appeal.

Understanding Aluminum Extrusion and its Advantages

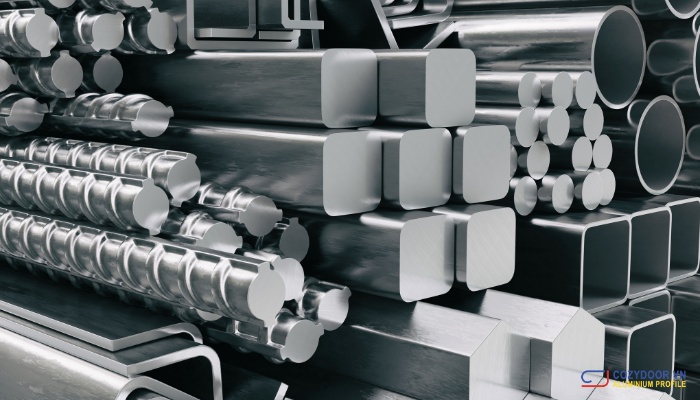

Aluminum extrusion is a manufacturing process that shapes aluminum by forcing it through a die, resulting in various profiles that can be used across multiple industries, including construction. This method is favored for its ability to create complex shapes while maintaining high strength and low weight. The versatility of extruded aluminum allows for innovative designs that meet specific project requirements, making it an ideal choice for directors and project managers in industrial construction.

What is the aluminum extrusion process?

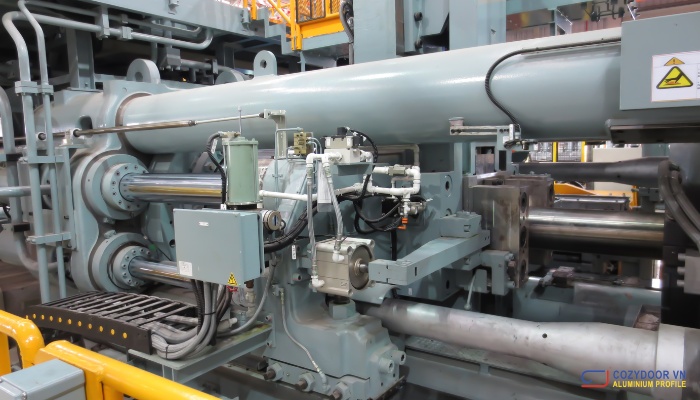

The aluminum extrusion process involves several key steps:

- Billet Preparation: Aluminum billets are heated to a specific temperature to enhance ductility.

- Extrusion: The heated billet is placed in an extrusion press, where a ram pushes it through a die, forming the desired shape.

- Cooling: The extruded shape is cooled, usually by air or water, to solidify it.

- Cutting: Once cooled, the extruded aluminum is cut into desired lengths for further processing or delivery.

This process can be categorized into different types based on the temperature and method used, including direct, indirect, hot, warm, and cold extrusion.

Key advantages of extruded aluminum over other materials

Extruded aluminum offers numerous benefits that make it a preferred material in construction:

- Lightweight yet Strong: Aluminum has a high strength-to-weight ratio, making it easier to handle and transport while providing structural integrity.

- Corrosion Resistance: Naturally resistant to corrosion, aluminum requires less maintenance compared to other metals.

- Design Flexibility: The extrusion process allows for intricate designs that can meet aesthetic and functional requirements.

- Cost-Effectiveness: With its recyclability and low material costs, extruded aluminum can significantly reduce overall project expenses.

Comparing extruded aluminum to aluminum sheet, plate, and castings

When choosing materials for construction projects, it’s essential to understand the differences between extruded aluminum and other forms like sheets, plates, and castings:

| Material Type | Strength | Weight | Cost | Applications |

| Extruded Aluminum | High | Low | Moderate | Structural components, frames |

| Aluminum Sheet | Moderate | Low | Low | Panels, cladding |

| Aluminum Plate | High | Moderate | High | Heavy-duty applications |

| Aluminum Casting | Very High | Moderate | High | Complex shapes requiring strength |

Extruded aluminum is often preferred for structural applications due to its strength and lightweight characteristics compared to sheets and plates.

Read more Blog & New:

The Types of Extruded Aluminum Alloys

Aluminum alloys play a crucial role in determining the properties of extruded products. Each alloy has unique characteristics that influence its suitability for various applications.

An overview of popular aluminum alloys

Some of the most commonly used alloys in extrusion include:

- 6061: Known for its excellent mechanical properties and weldability; ideal for structural applications.

- 6063: Offers good surface finish and is often used for architectural applications.

- 3003: Known for its excellent corrosion resistance; commonly used in chemical equipment.

Selecting the right alloy

Choosing the right alloy depends on several factors:

- Strength Requirements: Higher strength alloys like 6061 are suitable for load-bearing applications.

- Corrosion Resistance: Alloys like 3003 are better suited for environments prone to corrosion.

- Weldability: If welding is required in assembly, selecting an alloy with good weldability is crucial.

Relationship between alloy composition, properties, and performance

The composition of an alloy directly affects its properties such as tensile strength, corrosion resistance, and machinability. Understanding these relationships helps project managers make informed decisions when sourcing materials.

Standard and Custom Extruded Aluminum

Aluminum extrusions can be categorized into standard profiles or custom designs based on project needs.

Common standard aluminum profile shapes

Standard profiles include:

- Hollow beams

- Channels

- Angles

These profiles are readily available and suitable for various construction applications.

The process of designing and ordering custom extruded aluminum profiles

For projects requiring specific dimensions or shapes not available in standard profiles:

- Consultation: Discuss design requirements with suppliers like Cozydoor.

- Design Submission: Provide detailed drawings or specifications.

- Prototype Development: Review prototypes before full production.

- Production Order: Once approved, place orders for the required quantities.

This process ensures that all technical specifications are met while optimizing costs.

Achieving precise dimensions and tolerances with extruded aluminum

Extrusion allows manufacturers to achieve tight tolerances on dimensions. This precision is critical in ensuring that components fit together seamlessly during assembly.

Key Applications of Extruded Aluminum

Extruded aluminum finds extensive use across multiple sectors due to its advantageous properties.

Extruded aluminum in building construction

In construction, extruded aluminum is utilized for window frames, door frames, roofing systems, and structural supports due to its durability and aesthetic appeal.

Applications of extruded aluminum in the automotive and aerospace sectors

In automotive manufacturing, extrusions are used for lightweight frames and components that enhance fuel efficiency. In aerospace, they provide structural integrity without adding excessive weight.

Utilizing extruded aluminum for heat sinks and other specialized components

Extrusions are also critical in producing heat sinks for electronic devices due to their excellent thermal conductivity. This application underscores the versatility of extruded aluminum across industries.

The importance of Extruded Aluminum Profiles in various industries

The adaptability of extruded aluminum profiles makes them essential in various industries ranging from construction to electronics. Their ability to meet stringent technical specifications while remaining cost-effective positions them as a go-to material for directors and project managers seeking reliable solutions. For tailored advice on selecting the right types of extruded aluminum for your next project or to receive competitive pricing from Cozydoor‘s extensive range of products, please fill out your contact information below. Our experts are ready to assist you in optimizing your designs while ensuring timely delivery!

Aluminum Plate: The Key to Modern Construction Success

Cozydoor, a leading provider of high-quality aluminum plate materials, understands [...]

Nov

Mastering the Conductivity of Al for Optimal Project Success

One key factor often overlooked is the strategic selection of [...]

Nov

What is the Modulus of Aluminium? Easy Explanation Here!

This seemingly technical term holds the key to unlocking the [...]

Nov

Understanding the Environmental Impact of Aluminum Production

As a director or project manager in industrial construction, you’re [...]

Nov

The Power of Aluminum Extrusion Profiles in Construction

Tired of the same old construction materials? Want to elevate [...]

Nov

5 Types of Anodizing to Elevate Your Construction Projects

Understanding the Different Types of Anodizing Anodizing is an electrochemical [...]

Nov

Can You Recycle Aluminum? The Science Behind It Explained

In the ever-evolving landscape of construction, sustainability is no longer [...]

Nov

Top 5 Benefits of Aluminum Casting You Should Know

Are you a construction project manager seeking to revolutionize your [...]

Nov