As a director or project manager in industrial construction, you’re constantly juggling competing priorities: staying on schedule, keeping costs down, and ensuring worker safety. In today’s fast-paced environment, choosing the right materials is more critical than ever. Structural aluminum offers a powerful solution, delivering exceptional strength, durability, and cost-effectiveness.

At Cozydoor, we understand the challenges you face, and we’re dedicated to providing premium structural aluminum solutions that help you build better, faster, and smarter. This comprehensive guide will unlock the key benefits of structural aluminum and empower you to make informed decisions that elevate your next project.

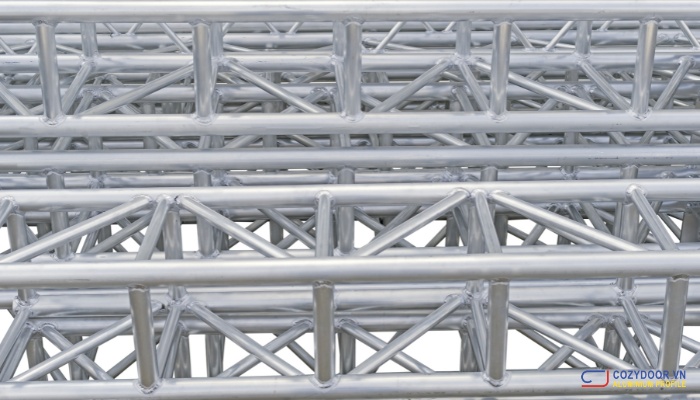

The Properties of Structural Aluminum

Understanding the inherent properties of structural aluminum is crucial for leveraging its full potential. Unlike other materials like steel, structural aluminum boasts a remarkable strength-to-weight ratio, meaning you get exceptional strength without the burden of excessive weight. This translates directly to cost savings in transportation, foundation design, and installation.

Moreover, aluminum’s natural resistance to corrosion minimizes maintenance needs and extends the lifespan of your structures, adding further value to your investment.

At Cozydoor, we meticulously select and test our aluminum alloys to guarantee superior performance and lasting value for your projects. Let’s delve into the specific properties that set structural aluminum apart.

Strength and Durability

Structural aluminum alloys, particularly 6061 and 7075, are renowned for their high tensile and yield strengths. These alloys can withstand significant stress and strain, making them ideal for demanding applications in industrial construction.

Independent testing by organizations like the Aluminum Association consistently demonstrates the exceptional durability of these alloys, often exceeding the performance of traditional steel in certain applications. This robust strength ensures the long-term structural integrity of your projects, minimizing the risk of costly repairs and downtime.

Lightweight Nature

The lightweight nature of structural aluminum offers significant advantages throughout the construction process. Reduced weight translates to lower transportation costs, easier handling on site, and faster installation times. This increased efficiency can significantly impact your project timelines and overall budget.

A study published in the Journal of Construction Engineering and Management demonstrated a 20% reduction in installation time when using aluminum framing compared to steel in a warehouse project. This lightweight advantage can be a game-changer for projects with tight deadlines.

Corrosion Resistance

Aluminum possesses inherent corrosion resistance thanks to a protective oxide layer that forms naturally on its surface. This natural barrier protects the metal from the elements, reducing the need for costly and time-consuming maintenance.

For even greater protection in harsh environments, Cozydoor offers a range of surface treatments like anodizing and powder coating, further enhancing corrosion resistance and adding aesthetic appeal.

Applications of Structural Aluminum Across Industries

The unique combination of strength, lightweight, and corrosion resistance makes structural aluminum a versatile choice across various industries, particularly within industrial construction. From expansive warehouses and bustling shopping centers to state-of-the-art factories, structural aluminum is transforming the way we build.

Its adaptability allows for innovative designs and efficient construction practices, meeting the diverse needs of modern industrial projects. Let’s explore some specific applications where structural aluminum truly shines.

Construction and Architecture

Structural aluminum is increasingly prevalent in modern construction, offering architects and contractors a flexible and high-performance material. Aluminum framing systems provide a lightweight yet robust solution for building structures, while aluminum curtain walls add a sleek, modern aesthetic.

For large-span structures like warehouses and shopping malls, aluminum’s high strength-to-weight ratio allows for wider column spacing and increased usable floor space. Cozydoor’s extensive range of aluminum structural shapes empowers architects to bring their most ambitious visions to life.

Transportation (Automotive and Aerospace)

The transportation industry constantly seeks ways to improve fuel efficiency and performance, making lightweight materials like structural aluminum essential. In automotive manufacturing, aluminum is used in car bodies, frames, and engine components to reduce vehicle weight and improve mileage.

Similarly, the aerospace industry relies on aluminum alloys for aircraft construction, leveraging their strength and lightweight to enhance flight performance and reduce fuel consumption.

Industrial Manufacturing

Structural aluminum plays a vital role in industrial manufacturing, providing a robust and reliable material for a wide range of applications. Aluminum framing is commonly used in the construction of machinery, robotic systems, and conveyor belts.

Its corrosion resistance makes it ideal for harsh industrial environments, while its lightweight nature allows for greater flexibility in design and operation.

Read more Blog & New:

Choosing the Right Structural Aluminum: Alloys and Forms

Selecting the correct aluminum alloy and form is paramount for project success. With a variety of options available, understanding the nuances of each is crucial. Cozydoor offers a comprehensive selection of aluminum alloys, including the popular 6061 and 7075, each with specific properties suited for different applications.

Our team of experts can guide you through the selection process, ensuring you choose the optimal material for your project’s specific needs. Let’s delve into the key considerations for choosing the right aluminum alloy and form.

Common Aluminum Alloys

Different aluminum alloys offer varying levels of strength, corrosion resistance, and weldability. 6061 aluminum is known for its versatility and good overall performance, making it suitable for a wide range of applications. 7075 aluminum, on the other hand, boasts exceptionally high strength, making it ideal for demanding structural applications.

Cozydoor provides detailed specifications for each alloy, empowering you to make informed decisions based on your project requirements.

Shapes and Profiles

Cozydoor offers a wide variety of aluminum structural shapes, including I-beams, channels, angles, and custom extrusions. Choosing the appropriate shape is essential for optimizing structural performance and minimizing material waste. Our experienced engineers can assist you in selecting the optimal profiles for your project, ensuring efficient use of materials and maximizing structural integrity.

We also offer custom extrusion services, allowing you to create unique shapes tailored to your specific design requirements.

Working with Structural Aluminum

Proper fabrication and design are crucial for maximizing the benefits of structural aluminum. At Cozydoor, we offer expert fabrication services, utilizing state-of-the-art equipment and skilled technicians to ensure precise and high-quality results.

Our team works closely with you throughout the design process, providing technical expertise and guidance to ensure your project meets all structural requirements. We leverage advanced design software and analysis tools to optimize structural performance, minimize material usage, and ensure the long-term stability of your project. Let’s explore the key aspects of fabrication and design.

Fabrication Techniques

Cozydoor employs a range of advanced fabrication techniques, including welding, cutting, and machining, to create precise and high-quality aluminum components. Our certified welders utilize the latest welding procedures to ensure strong and reliable joints, while our precision machining capabilities allow us to create complex shapes and profiles with tight tolerances.

We maintain rigorous quality control standards throughout the fabrication process, ensuring every component meets our exacting specifications.

Design Considerations

Effective structural design is essential for maximizing the benefits of aluminum. Our experienced engineers consider factors such as load-bearing capacity, stress distribution, and connection design to ensure the structural integrity of your project.

We utilize advanced software tools, like Finite Element Analysis (FEA), to simulate real-world conditions and optimize structural performance. Our collaborative design process ensures your project meets all technical requirements while minimizing material usage and maximizing cost-effectiveness.

Sustainability and the Future of Structural Aluminum

In today’s world, sustainability is no longer an option—it’s a necessity. Structural aluminum’s exceptional recyclability makes it a responsible choice for environmentally conscious construction.

At Cozydoor, we’re committed to sustainable practices, sourcing recycled aluminum whenever possible and minimizing waste throughout our operations. By choosing structural aluminum from Cozydoor, you’re not only investing in a high-performance material but also contributing to a more sustainable future. Let’s delve deeper into the environmental benefits of structural aluminum.

Recyclability

Aluminum is infinitely recyclable without losing its inherent properties. This means that aluminum scrap can be remelted and reused repeatedly, minimizing the need for new aluminum production. The aluminum recycling process consumes significantly less energy than producing primary aluminum, reducing greenhouse gas emissions and conserving valuable natural resources.

By choosing Cozydoor’s structural aluminum, you’re actively participating in a closed-loop system that minimizes environmental impact.

Life-Cycle Considerations

Structural aluminum’s durability and recyclability contribute to its exceptional life-cycle performance. The long lifespan of aluminum structures reduces the need for frequent replacements, minimizing material consumption and waste generation.

At the end of its useful life, aluminum can be easily recycled, further reducing its environmental footprint. By considering the entire life cycle of your building materials, you can make informed decisions that minimize environmental impact and maximize long-term value.

Ready to experience the Cozydoor difference? Contact us today for a free consultation and discover how our premium structural aluminum solutions can transform your next project. Our team of experts will provide personalized guidance, helping you select the optimal materials, optimize your designs, and achieve unprecedented project success. Fill out the form below to request a quote and unlock the full potential of structural aluminum.

10 Amazing Things Made by Aluminium You Didn’t Know About

Imagine sleek, modern structures rising against the skyline – lightweight [...]

Nov

How Aluminium Recycling Helps Protect Our Environment

As a director or project manager in industrial construction, you’re [...]

Nov

Discover the Benefits of 7000 Series Aluminum Today

As a project manager in industrial construction, you’re constantly juggling [...]

Nov

The Power of Miniature Extrusions in Construction

What are Miniature Extrusions? Miniature extrusions are precision-engineered aluminum profiles [...]

Nov

How is Aluminum Produced? Aluminum Production

Aluminum isn’t simply dug out of the ground like gold. [...]

Nov

Aluminum Extruded Products: Durable and Cost-Effective Choices

Cozydoor, a leading provider of aluminum extruded products, is here [...]

Nov

When Was Aluminum Discovered? A Brief History

Why should you care about the history of aluminum? Understanding [...]

Nov

ADC12 Aluminum: A Strong, Lightweight Solution for All Needs

Are you a director or project manager in industrial construction [...]

Nov