As a project manager in industrial construction, you’re constantly juggling competing priorities. Deadlines loom, budgets tighten, and the need for durable, high-performance materials is paramount. What if there was a single material that could help you tackle all these challenges? Enter 7000 series aluminum, a game-changing alloy revolutionizing how we build factories, warehouses, and shopping centers. This comprehensive guide will explore the remarkable properties, applications, and sustainability of 7000 series aluminum, empowering you to make informed decisions that drive project success. Ready to unlock the full potential of your next construction project? Let’s dive in!

What is 7000 Series Aluminum?

7000 series aluminum alloys are primarily composed of zinc as the major alloying element, which provides exceptional strength and durability. These alloys are known for their high strength-to-weight ratio, making them ideal for applications where weight savings are crucial without compromising structural integrity. The 7000 series also includes other elements such as magnesium, copper, and chromium, which enhance specific properties like corrosion resistance and machinability.

The versatility of 7000 series aluminum makes it a preferred choice in various industries, particularly in aerospace and construction. For directors and project managers in industrial construction, understanding the unique features of this aluminum series can lead to better material selection and optimized designs that meet both aesthetic and functional requirements.

In terms of sourcing, companies like Cozydoor offer competitive pricing and reliable delivery schedules, ensuring that construction projects stay on track without overspending on materials. This is particularly important for professionals looking to reduce costs while maintaining high standards of quality.

Key Features of 7000 Series Aluminum

- High Strength:

7000 series aluminum is renowned for its strength, often used in applications requiring robust materials. Its tensile strength can exceed 700 MPa, making it suitable for demanding environments.

- Lightweight:

Despite its strength, 7000 series aluminum is lightweight compared to steel, which contributes to lower transportation costs and easier handling on-site.

- Corrosion Resistance:

These alloys exhibit excellent resistance to corrosion, especially when treated with protective coatings. This characteristic is vital for long-lasting structures exposed to various environmental conditions.

- Formability:

While high-strength alloys can be challenging to form, advancements in processing techniques have improved the workability of 7000 series aluminum, allowing for complex shapes without sacrificing performance.

Understanding the Role of Alloying Elements

The performance characteristics of 7000 series aluminum are significantly influenced by its alloying elements:

- Zinc (Zn): The primary alloying element that enhances strength.

- Magnesium (Mg): Improves corrosion resistance and weldability.

- Copper (Cu): Increases strength but can reduce corrosion resistance if not managed properly.

- Chromium (Cr): Enhances overall strength and improves resistance to stress corrosion cracking.

By carefully selecting these elements during production, manufacturers can tailor the properties of 7000 series aluminum to meet specific project requirements.

The Mechanical Properties of 7000 Series Aluminum

Tensile Strength and Yield Strength: Key Performance Indicators

Tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before failing. Yield strength indicates the maximum stress that a material can endure without permanent deformation. For instance, certain alloys within the 7000 series can achieve yield strengths around 500 MPa or higher, making them suitable for structural applications where safety is paramount.

Understanding the Importance of Tempers

The tempering process significantly affects the mechanical properties of aluminum alloys. Common tempers for 7000 series include T6 (solution heat-treated and artificially aged) and T651 (solution heat-treated, stretched to eliminate internal stresses). These processes enhance the material’s strength while maintaining ductility.

The High Strength-to-Weight Ratio: A Critical Advantage

The combination of high strength and low weight makes 7000 series aluminum an excellent choice for industries such as aerospace where every kilogram counts. This advantage translates into increased efficiency in fuel consumption and overall performance in aircraft design.

Read more Blog & New:

Applications of 7000 Series Aluminum

Aerospace Applications: The Ideal Choice for Aircraft Construction

In aerospace manufacturing, where safety and performance are critical, 7000 series aluminum is widely used for aircraft structures including fuselages and wings due to its superior strength-to-weight ratio.

Beyond Aerospace: Applications in Diverse Industries

Beyond aerospace, these alloys find applications in automotive components, sporting equipment, marine structures, and military vehicles. Their versatility makes them suitable for any project requiring reliable performance under stress.

Real-World Examples: Components Made from 7000 Series Aluminum

Several high-profile projects utilize 7000 series aluminum components:

- Boeing 787 Dreamliner: Uses extensive amounts of this alloy in its airframe.

- Automotive Racing: Components like chassis and suspension parts benefit from its lightweight properties.

- Military Vehicles: Armor plating made from these alloys provides both protection and mobility.

Corrosion Resistance: A Key Advantage of 7000 Series Aluminum

Natural Corrosion Resistance: A Built-in Advantage

Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent further oxidation. However, specific treatments enhance this property further in the case of 7000 series alloys.

Surface Treatments: Enhancing Corrosion Resistance

Surface treatments such as anodizing or powder coating can significantly improve corrosion resistance. These processes not only protect against environmental factors but also provide aesthetic finishes that enhance the visual appeal of structures.

Understanding and Preventing Stress Corrosion Cracking

Stress corrosion cracking (SCC) is a concern with high-strength alloys like those in the 7000 series. Understanding how to mitigate this risk through proper design practices and material selection is crucial for ensuring long-term performance.

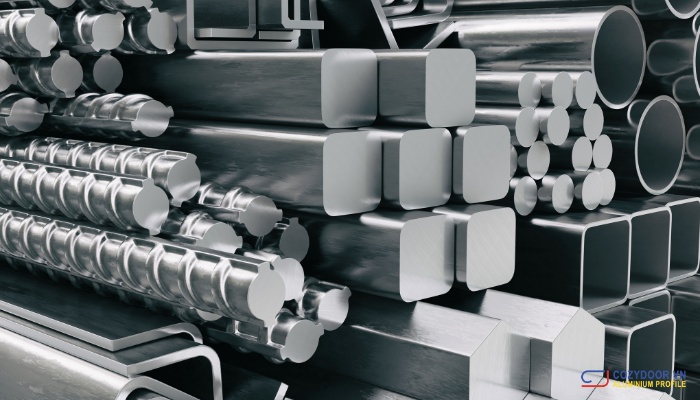

Manufacturing and Processing 7000 Series Aluminum

Extrusion, Forging, and Rolling: Shaping 7000 Series Aluminum

Processing techniques such as extrusion allow manufacturers to create complex shapes while maintaining material integrity. Forging provides additional strength through deformation processes that align the grain structure.

Heat Treatment: Enhancing Strength and Durability

Heat treatment processes are essential for achieving desired mechanical properties in 7000 series aluminum. These treatments can significantly enhance both yield strength and ductility.

Machining and Tooling: Key Aspects of Processing

Machining these alloys requires specialized tooling due to their hardness compared to other aluminum grades. Understanding optimal machining parameters is essential for minimizing tool wear and ensuring precision in component manufacturing.

Understanding the Sustainability of 7000 Series Aluminum

Aluminum Production: Environmental Considerations and Solutions

The production of aluminum has environmental impacts; however, advancements in recycling technologies have made it one of the most sustainable metals available today. The recycling process requires only about 5% of the energy needed to produce new aluminum from ore.

Sustainable Sourcing and Manufacturing: A Growing Focus

Many suppliers are now focusing on sustainable practices throughout their supply chains. Cozydoor emphasizes sourcing materials responsibly while optimizing production processes to reduce waste—benefits that resonate with environmentally conscious clients.

In conclusion, selecting 7000 series aluminum offers numerous advantages for industrial construction projects aiming to optimize costs while ensuring safety and durability. By partnering with reliable suppliers like Cozydoor who understand these needs, project managers can achieve their goals effectively. For personalized consultations on how aluminium 7000 series can fit into your next project, please fill out our contact form to receive preferential pricing!

Aluminum Beverage Cans: A Surprisingly Powerful Resource

Tired of costly materials and construction delays? Imagine harnessing the [...]

Nov

Anodized Aluminum: A Sustainable Material Choice

Are you tired of battling escalating material costs, tight deadlines, [...]

Nov

Discover the Different Types of Aluminum and Their Uses

The right aluminum can elevate your construction to new heights, [...]

Nov

7 Secrets to Mastering Aluminum Alloy in Industrial Construction

Are you tired of budget overruns and project delays? Discover [...]

Nov

Aircraft Grade Aluminum: Strong, Lightweight, and Reliable

In the competitive landscape of industrial construction, selecting the right [...]

Nov

Feel the Strength of Magnitude 7 Metals in Action

As a project manager, you understand the responsibility of building [...]

Nov

How the Aluminum Recycling Process Can Save Your Project

As a director or project manager in industrial construction, you’re [...]

Nov

Alum Can Recycle: Slash Construction Waste

In the fast-paced world of industrial construction, project managers and [...]

Nov