Are you tired of costly design overruns and unpredictable material delays? Imagine a world where your construction projects flow seamlessly, material costs are optimized, and every element meets the highest standards of durability and performance.

Cozydoor is here to help you achieve that vision. We understand that as a project manager, you’re constantly looking for ways to improve efficiency, reduce costs, and deliver exceptional results. That’s why we’ve compiled this comprehensive guide to the resistivity of aluminum, a crucial property that influences the performance of aluminum in your construction projects.

Understanding Resistivity of Aluminum: A Comprehensive Guide

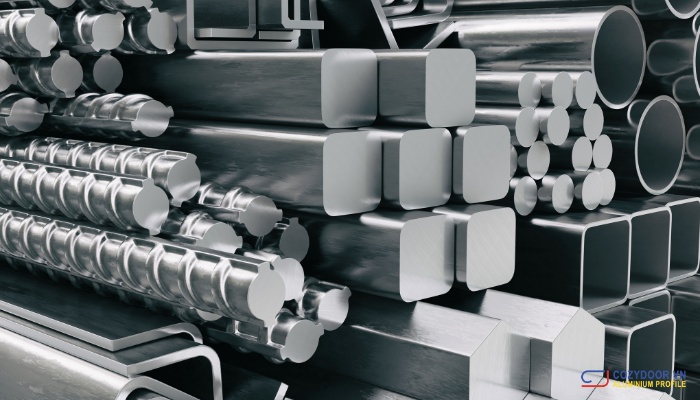

Aluminum is a remarkably versatile metal, widely used in a multitude of construction applications, from intricate structural elements to sleek, modern façades. But beneath its gleaming surface lies a fundamental property that plays a pivotal role in its performance – resistivity.

What is Resistivity?

In simple terms, resistivity is a measure of how strongly a material resists the flow of electricity. The higher the resistivity, the more difficult it is for electricity to pass through it. Aluminum, despite being a highly conductive metal, possesses a specific level of resistivity. Understanding this property is key to unlocking its full potential in your projects.

Factors Affecting Aluminum Resistivity

The resistivity of aluminum isn’t static; it can be influenced by several factors:

- Temperature: As temperature increases, the atoms in aluminum vibrate more vigorously, hindering the flow of electrons and leading to increased resistivity.

- Alloying Elements: Adding other metals to create aluminum alloys can significantly impact resistivity. For instance, adding magnesium or silicon can increase resistivity, making the alloy suitable for specific applications where resistance to current flow is desired.

- Processing Methods: Manufacturing processes like rolling, extrusion, and annealing can influence grain size and surface finish, ultimately affecting resistivity.

Comparing Aluminum Resistivity to Other Metals

Aluminum’s resistivity is frequently compared to other commonly used metals, like copper, gold, and silver.

| Metal | Resistivity (Ω·m at 20°C) |

| Silver | 1.59 x 10^-8 |

| Copper | 1.68 x 10^-8 |

| Gold | 2.44 x 10^-8 |

| Aluminum | 2.65 x 10^-8 |

This table highlights that while aluminum has a slightly higher resistivity than copper and gold, it’s still a highly conductive metal, offering excellent electrical performance. Its advantage lies in its lightweight nature and affordability, making it a preferred choice in many applications.

Applications of Aluminum Resistivity

The unique combination of aluminum’s high conductivity and manageable resistivity enables a wide range of applications in construction projects:

- Electrical Wiring: Aluminum’s conductivity makes it ideal for electrical wiring in buildings, factories, and warehouses. Its lightweight nature reduces installation costs, and its resistance to corrosion ensures long-term durability.

- Electronics: In electronic components, aluminum’s resistivity plays a role in controlling the flow of electricity, influencing the performance and efficiency of electronic circuits.

- Heat Transfer: The controlled heat dissipation offered by aluminum’s resistivity makes it valuable in heat exchangers and cooling systems, ensuring optimal temperature regulation.

Measuring Aluminum Resistivity

To accurately determine the resistivity of aluminum, specialized instruments and techniques are employed. These methods involve measuring the resistance of a known length and cross-sectional area of aluminum material, allowing for the calculation of resistivity.

Read more Blog & New:

Aluminum Alloys and Resistivity

The use of aluminum alloys significantly expands the application range of aluminum in construction projects.

Aluminum Alloy 6061

One of the most common aluminum alloys, 6061, is prized for its strength, weldability, and good corrosion resistance. Its resistivity is slightly higher than pure aluminum, making it suitable for applications where controlled resistance is desirable.

Other Common Aluminum Alloys

Numerous other aluminum alloys are available, each offering unique combinations of properties. The choice of alloy depends on the specific requirements of the application, including desired resistivity levels, strength, and corrosion resistance.

Choosing the Right Aluminum Alloy

Selecting the appropriate aluminum alloy is crucial for ensuring project success. Factors to consider include:

- Required Resistivity: Different alloys exhibit varying resistivity levels, influencing their electrical and thermal performance.

- Strength and Durability: Choose an alloy that meets the strength and durability demands of your project.

- Corrosion Resistance: Select an alloy that offers adequate corrosion resistance for your specific environment.

- Cost: Compare the cost of different alloys to identify the most economical option.

Resistivity of Aluminum Wire

Aluminum wires are commonly used in electrical wiring systems due to their high conductivity, lightweight nature, and affordability.

Wire Gauge and Resistivity

Wire gauge refers to the diameter of the wire. The smaller the gauge number, the thicker the wire. Resistivity is influenced by the wire gauge, with thicker wires exhibiting lower resistance.

Calculating Wire Resistance

The resistance of an aluminum wire can be calculated using the following formula:

R = ρ (L / A)

where:

- R = Resistance (Ω)

- ρ = Resistivity of aluminum (Ω·m)

- L = Length of the wire (m)

- A = Cross-sectional area of the wire (m²)

Wire Resistance in Electrical Circuits

Wire resistance is a crucial factor in electrical circuit design. It affects current flow, voltage drop, and heat dissipation.

Resistivity of Aluminum Foil

Aluminum foil, a thin and versatile sheet of aluminum, has a wide range of applications, from food packaging to electrical insulation.

Foil Thickness and Resistivity

The thickness of aluminum foil directly impacts its resistivity. Thicker foil generally has lower resistance, while thinner foil exhibits higher resistance.

Resistivity of Aluminum Foil in Packaging

Aluminum foil’s high barrier properties make it an ideal material for food packaging. Its resistivity ensures minimal heat transfer, prolonging shelf life and preserving food quality.

Aluminum Foil in Electronic Applications

Aluminum foil’s conductivity and its ability to be easily formed into various shapes make it valuable in electronic applications, such as capacitors and electrical insulation.

At Cozydoor, we are committed to providing you with the highest quality aluminum materials and expert guidance to elevate your construction projects.

Get in touch with our team today!

Alum Can Recycle: Slash Construction Waste

In the fast-paced world of industrial construction, project managers and [...]

Nov

The Ultimate Guide to Aluminum Extrusion Dies

This comprehensive guide will equip you with the knowledge and [...]

Nov

Aircraft Grade Aluminum: Strong, Lightweight, and Reliable

In the competitive landscape of industrial construction, selecting the right [...]

Nov

7 Secrets of Structural Aluminum: Slash Costs & Boost Project Success

As a director or project manager in industrial construction, you’re [...]

Nov

Common Aluminum Grades: What You Need to Know

In the world of industrial construction, selecting the right materials [...]

Nov

What Happens Inside an Aluminum Refinery? Find Out!

This comprehensive guide will walk you through the fascinating world [...]

Nov

Aluminum Extruded Products: Durable and Cost-Effective Choices

Cozydoor, a leading provider of aluminum extruded products, is here [...]

Nov

The Ultimate Guide to Stainless Steel Recycling

Why Stainless Steel Recycling Matters in Today’s Construction Industry As [...]

Nov