Are you a construction project manager seeking a robust, versatile, and cost-effective material for your next industrial project? Look no further than 6061 T6 aluminum. This remarkable alloy offers an exceptional balance of strength, workability, and corrosion resistance, making it ideal for factories, warehouses, and shopping centers. Cozydoor is your trusted partner in harnessing the full potential of 6061 T6 aluminum. Let us guide you through its remarkable properties, sourcing strategies, and machining techniques to ensure your projects are completed on time, within budget, and to the highest standards.

Understanding the Properties of 6061 T6 Aluminum

6061-T6 aluminum is a widely used alloy known for its exceptional strength and versatility, making it a popular choice in various industries, particularly in construction and manufacturing. This alloy is part of the 6000 series of aluminum alloys and is characterized by its excellent mechanical properties, including high tensile strength, good corrosion resistance, and excellent machinability. The T6 temper indicates that the material has undergone solution heat treatment followed by artificial aging, which enhances its strength and durability.

Tensile Strength and Yield Strength

6061-T6 aluminum exhibits an ultimate tensile strength (UTS) of approximately 310 MPa (45,000 psi) and a yield strength of around 276 MPa (40,000 psi). These values indicate that the material can withstand substantial loads without deformation, making it ideal for structural applications in factories and warehouses. When selecting materials for construction projects, these mechanical properties ensure that structures remain safe and stable under various conditions.

Elongation and Ductility

The elongation at break for 6061-T6 aluminum is typically around 12%, which reflects its ductility — the ability to deform under tensile stress without fracturing. This property is particularly beneficial during fabrication processes, as it allows for easier shaping and forming of components without compromising structural integrity.

Density and Weight Considerations

With a density of approximately 2.7 g/cm³ (0.0975 lb/in³), 6061-T6 aluminum strikes a balance between strength and weight. This lightweight characteristic is advantageous in construction, where reducing overall weight can lead to lower transportation costs and easier handling on-site.

Machinability and Fabrication

One of the standout features of 6061-T6 aluminum is its excellent machinability. It can be easily cut, drilled, and formed into complex shapes while maintaining dimensional accuracy. This quality is essential for project managers looking to optimize production efficiency and minimize technical errors during fabrication.

Weldability and Joining Techniques

Welding 6061-T6 aluminum can be accomplished using various methods such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. Proper preparation and selection of filler materials are vital to achieving strong welds. The ability to weld this alloy effectively enhances its application range in construction projects where joining components is necessary.

Corrosion Resistance in Various Environments

6061-T6 aluminum exhibits excellent corrosion resistance due to its natural oxide layer formation. This property makes it suitable for outdoor applications, ensuring longevity even in harsh environments such as coastal areas or industrial settings where exposure to moisture or chemicals may occur.

Heat Treatment and Its Impact on Properties

The heat treatment process that 6061-T6 undergoes significantly enhances its mechanical properties. By subjecting the alloy to solution heat treatment followed by aging, manufacturers can achieve optimal strength levels while ensuring that the material retains its workability. Understanding this process helps project managers make informed decisions regarding material selection based on specific project requirements.

Sourcing and Purchasing 6061-T6

Finding reliable suppliers for 6061-T6 aluminum is crucial for project managers aiming to meet construction deadlines while optimizing costs. Here’s how to navigate sourcing effectively.

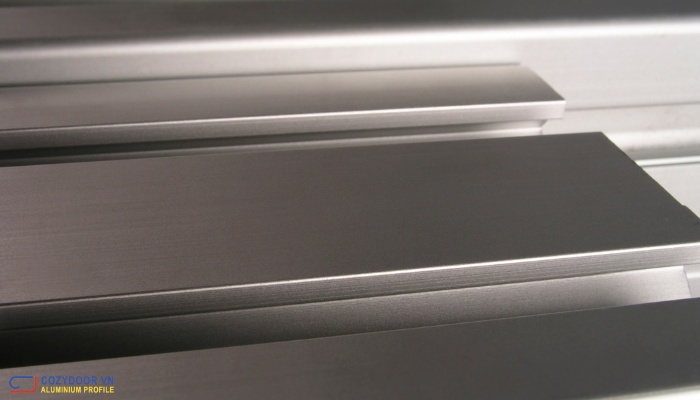

Common Forms and Sizes Available (Sheet, Plate, Bar, Extrusion)

6061-T6 aluminum is available in various forms including sheets, plates, bars, and extrusions. Each form serves different applications; for instance:

- Sheets are commonly used for panels.

- Plates are ideal for structural components.

- Bars are often utilized in machining processes.

- Extrusions allow for complex shapes needed in architectural designs.

Understanding the available forms helps project managers select the right type for their specific needs.

Identifying Reputable Suppliers and Distributors

To ensure high-quality procurement of 6061-T6 aluminum, it’s vital to identify reputable suppliers. Look for companies with established track records in the industry, positive customer reviews, and certifications that guarantee material quality. Engaging with suppliers who offer transparent pricing models can also aid in budget management.

Factors Affecting Price (Quantity, Form, Processing)

The price of 6061-T6 aluminum can vary based on several factors including order quantity, form selected (sheet vs. extrusion), and any additional processing required. Understanding these variables allows project managers to negotiate better deals while ensuring they receive the right material specifications.

Navigating Minimum Order Quantities and Lead Times

When sourcing materials like 6061-T6 aluminum, be aware of minimum order quantities (MOQs) set by suppliers. These MOQs can impact budget planning if larger quantities than needed must be purchased. Additionally, understanding lead times ensures that materials arrive on-site when required to avoid delays in construction timelines.

Read more Blog & New:

Machining and Processing 6061-T6 Aluminum

Efficient machining processes are critical when working with 6061-T6 aluminum to ensure high-quality outputs while minimizing waste. Here’s how to optimize machining operations effectively.

Recommended Cutting Speeds and Feeds for Different Operations

When machining 6061-T6 aluminum, selecting appropriate cutting speeds and feeds is essential. Generally:

- Milling: Cutting speeds of around 300-600 SFM (surface feet per minute) are recommended.

- Turning: Speeds between 400-800 RPM work well depending on tool diameter.

- Drilling: Utilize speeds around 100-200 RPM with appropriate feed rates based on drill size.

These guidelines help achieve optimal results while prolonging tool life.

Tooling Selection and Considerations

Choosing the right tooling is crucial when working with 6061-T6 aluminum. High-speed steel (HSS) or carbide tools are typically recommended due to their durability. Additionally, consider coatings such as TiN (Titanium Nitride) to enhance tool performance during machining operations.

Best Practices for Milling, Drilling, and Turning

Implementing best practices during machining processes ensures consistency in quality:

- Milling: Maintain proper coolant flow to prevent overheating.

- Drilling: Use peck drilling techniques for deeper holes.

- Turning: Ensure proper alignment to avoid vibrations that could affect precision.

These practices contribute to smoother operations while minimizing technical errors.

Surface Finishing Techniques

Achieving a high-quality surface finish on machined components made from 6061-T6 aluminum enhances both aesthetics and functionality. Techniques such as anodizing not only improve appearance but also increase corrosion resistance. Other methods like bead blasting or polishing can further refine surface quality based on project requirements.

Comparing 6061-T6 Aluminum with Other Aluminum Alloys

Understanding how 6061-T6 compares with other aluminum alloys enables project managers to make informed decisions regarding material selection based on specific application needs.

| Feature | 6061-T6 | 6061-T651 | 6063 | 7075-T6 |

| Tensile Strength (ksi) | 45 | 42 | 35 | 83 |

| Yield Strength (ksi) | 40 | 35 | 31 | 73 |

| Elongation (%) | 10 | 12 | 12 | 8 |

| Machinability | Excellent | Excellent | Excellent | Good |

| Weldability | Good | Good | Excellent | Fair |

| Corrosion Resistance | Good | Good | Excellent | Good |

| Cost | Moderate | Moderate | Lower | Higher |

6061-T6 vs. 6061-T651: Subtle Differences in Temper

While both alloys belong to the same family, the T651 temper indicates additional stress relief processing compared to T6. This results in slightly improved mechanical properties making T651 more suitable for applications requiring enhanced dimensional stability after machining.

6061-T6 vs. 6063: Strength and Application Differences

Compared to 6063 aluminum alloy, which is often used for architectural applications due to its excellent extrudability but lower strength than T6 2, choosing between these alloys depends on whether strength or formability is prioritized in your project requirements.

6061-T6 vs. 7075: A Trade-off Between Strength and Cost

7075 aluminum alloy offers higher strength than 6061-T6 but at a higher cost. For projects where budget constraints are significant yet high performance is required—such as aerospace applications—understanding this trade-off becomes essential when selecting materials.

Choosing the Right Alloy for Your Specific Needs

Ultimately, selecting between different alloys hinges on understanding specific application requirements such as load-bearing capacity or environmental exposure conditions. Engaging with suppliers who provide detailed technical data can facilitate this decision-making process effectively.

Common Applications of 6061-T6

The versatility of 6061-T6 aluminum makes it suitable across various industries ranging from aerospace to construction. Understanding these applications helps directors align material choices with project goals effectively.

Aerospace Applications: Structural Components and Frames

In aerospace engineering, components made from 6061-T6 are frequently used due to their high strength-to-weight ratio which enhances fuel efficiency while maintaining structural integrity during flight operations.

Automotive Applications: Wheels and Chassis Parts

The automotive industry benefits from utilizing this alloy within suspension systems or engine components where lightweight yet robust materials are essential for performance optimization.

Construction and Architectural Uses

In construction projects involving frameworks or trusses designed under stringent safety standards—such as warehouses or shopping centers—utilizing durable materials like 6061-T6 ensures longevity while meeting aesthetic demands through anodizing options available post-fabrication.

Sporting Goods and Recreational Equipment

From bicycle frames to sports equipment like tennis rackets—this alloy provides athletes with reliable gear designed not only for performance but also durability over time under rigorous use conditions.

Other Industrial and Consumer Applications

Beyond specialized industries—common consumer products such as drinking bottles leverage lightweight properties alongside corrosion resistance offered by this versatile material ensuring functionality paired with style across everyday items used daily by families everywhere!

By understanding these facets regarding sourcing suppliers efficiently along with comprehensive insights into processing techniques—directors & project managers can streamline operations leading towards successful outcomes within their respective fields! For personalized consultation regarding your specific needs related towards acquiring high-quality material like 6061 T6 Aluminum, please provide your contact information below!

When Was Aluminum Discovered? A Brief History

Why should you care about the history of aluminum? Understanding [...]

Nov

Aluminum Screen Rooms: Enjoy Nature Without Bugs

One innovative application gaining traction is the aluminum screen room [...]

Nov

Aluminum Extruded Products: Durable and Cost-Effective Choices

Cozydoor, a leading provider of aluminum extruded products, is here [...]

Nov

The Ultimate Guide to Stainless Steel Recycling

Why Stainless Steel Recycling Matters in Today’s Construction Industry As [...]

Nov

5 Reasons Why Aluminum Sheet is the Smart Choice

Imagine a material that blends strength with lightness, resists corrosion, [...]

Nov

What Happens Inside an Aluminum Refinery? Find Out!

This comprehensive guide will walk you through the fascinating world [...]

Nov

Anodized Aluminum: A Sustainable Material Choice

Are you tired of battling escalating material costs, tight deadlines, [...]

Nov

Understanding the Environmental Impact of Aluminum Production

As a director or project manager in industrial construction, you’re [...]

Nov