Unlock the secrets to building smarter, stronger, and more cost-effective industrial structures. Choosing the right aluminum alloy can make or break your next construction project. 5052 and 6061 are two popular options, but knowing their strengths and limitations is crucial for making informed decisions. Get ready to level up your expertise with Cozydoor’s comprehensive guide, designed specifically for directors and project managers in industrial construction.

Key Differences Between 5052 Aluminum and 6061 Aluminum

Choosing between 5052 aluminum and 6061 aluminum requires understanding their key differences in terms of mechanical properties, corrosion resistance, weldability, and heat treatability.

Strength and Formability

5052 aluminum boasts superior strength and work hardening properties compared to 6061. This means it gets stronger as it’s formed, making it ideal for applications demanding high strength and resilience. Picture this: using 5052 for structural components like beams, columns, and frames, where resistance to bending and deformation is crucial.

6061 aluminum, on the other hand, is a heat-treatable alloy. This allows for increased strength through heat treatment processes, resulting in enhanced tensile and yield strength. Visualize: utilizing 6061 in applications where lightweight yet durable components are required, like aircraft parts, automotive components, and even specialized industrial machinery.

Here’s a table summarizing the key strength differences:

| Property | 5052 Aluminum | 6061 Aluminum |

| Tensile Strength | 290 MPa (Annealed) | 124 MPa (Annealed) – 310 MPa (T6) |

| Yield Strength | 125 MPa (Annealed) | 55 MPa (Annealed) – 276 MPa (T6) |

| Elongation | 20% (Annealed) | 30% (Annealed) – 12% (T6) |

| Work Hardening | Excellent | Good |

| Formability | Excellent (Annealed) | Good |

When choosing between 5052 and 6061, consider your project’s specific strength requirements and the need for heat treatment to achieve optimal properties.

Corrosion Resistance in Different Environments

Corrosion resistance is paramount in construction, especially when exposed to harsh elements. 5052 aluminum shines in this area. Its high magnesium content makes it exceptionally resistant to corrosion, particularly in marine environments. Imagine building a coastal warehouse with 5052 aluminum; you’re ensuring longevity and minimizing maintenance costs.

6061 aluminum offers good overall corrosion resistance, but its performance in harsh environments may not match 5052.

If your project involves exposure to salt spray, moisture, or other corrosive elements, 5052 is a superior choice.

Weldability and Machinability

Both 5052 and 6061 aluminum are considered highly weldable. However, the specific welding procedures and techniques may differ due to their alloying elements. 5052 aluminum typically requires specialized welding techniques to ensure consistent and reliable welds, while 6061 aluminum offers a more forgiving welding experience.

When it comes to machinability: 6061 aluminum generally takes the lead. Its composition makes it easier to machine, resulting in smoother cuts and less tool wear. Consider this: for projects requiring intricate parts or complex machining, 6061 might be the better choice.

Here’s a breakdown:

| Property | 5052 Aluminum | 6061 Aluminum |

| Weldability | Good | Excellent |

| Machinability | Good | Excellent |

Consulting a qualified welding expert is recommended for ensuring optimal welding results, regardless of the chosen alloy.

Heat Treatability

6061 aluminum is the clear winner here. It’s heat-treatable, meaning you can manipulate its strength and hardness through heat treatment processes. This opens a world of possibilities: for applications requiring enhanced strength, like structural elements in high-demand situations.

5052 aluminum, on the other hand, is not heat-treatable. Its strength properties are primarily determined by its composition and cold working processes.

If your project demands the highest strength possible, 6061 aluminum, with its heat treatment capabilities, is an excellent option.

Read more Blog & New:

Choosing the Right Aluminum Alloy for Your Application

Now that we’ve explored the key differences, let’s apply this knowledge to real-world construction scenarios.

Marine and Coastal Applications

5052 aluminum emerges as the champion for marine and coastal construction projects. Its superior corrosion resistance ensures long-term durability in the harsh coastal environment. Imagine:

- Building a seaside factory or warehouse: 5052 aluminum’s strength and resistance to salt spray will safeguard your investment for years to come.

- Constructing a pier or dock: Its resilience to saltwater exposure will ensure lasting structural integrity.

Cozydoor: “Our commitment to providing high-quality 5052 aluminum ensures reliable performance in challenging environments. Contact us for expert guidance on selecting the right product for your marine construction project.”

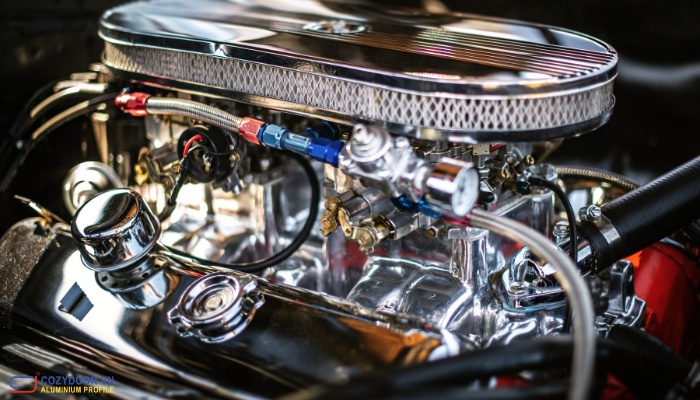

Automotive and Transportation Uses

Both 5052 and 6061 aluminum are frequently used in the automotive industry. Their lightweight yet durable properties make them ideal for various transportation applications.

- 5052 aluminum: Considered excellent for body panels, bumpers, and other structural elements due to its good formability and strength.

- 6061 aluminum: Often chosen for engine parts, suspension components, and frames, where high strength and heat treatment capabilities are beneficial.

Cozydoor: “We offer a wide range of 5052 and 6061 aluminum products specifically designed for automotive and transportation applications. Contact us to discuss your project’s unique needs and explore our solutions.”

Aerospace and Structural Components

For demanding aerospace applications, 6061 aluminum takes the spotlight. Its ability to be heat-treated to achieve higher strength makes it a top choice for aircraft components, where weight and structural integrity are paramount.

Think about this:

- Aircraft frames and wings: 6061 aluminum’s heat treatment capabilities ensure exceptional strength and lightweight design.

- Engine components: Its ability to withstand high temperatures and stresses makes it perfect for critical engine parts.

Cozydoor: “We understand the stringent demands of aerospace applications. Our 6061 aluminum meets the highest standards for strength, durability, and reliability. Contact us to discuss your specific aerospace needs.”

General Fabrication and Welding Projects

5052 and 6061 aluminum are both versatile materials for general fabrication and welding projects. The choice between them depends on your project’s specific requirements.

- 5052 aluminum: Its excellent formability and work hardening properties make it ideal for shaping and creating complex structures.

- 6061 aluminum: Its weldability and machinability make it suitable for intricate designs and large-scale welding projects.

Cozydoor: “We offer a comprehensive selection of 5052 and 6061 aluminum products for a variety of fabrication and welding applications. Contact us to discuss your specific project requirements and receive expert advice.”

Understanding Aluminum Alloy Properties

A deeper understanding of aluminum alloy properties is crucial for making informed decisions.

Mechanical Properties

Mechanical properties refer to a material’s response to applied forces. Here’s a breakdown of key mechanical properties for 5052 and 6061 aluminum:

- Tensile Strength: Measures the maximum stress a material can withstand before breaking.

- Yield Strength: Indicates the stress at which a material starts to deform permanently.

- Elongation: Measures a material’s ductility, or its ability to stretch before breaking.

- Hardness: Indicates a material’s resistance to indentation.

The mechanical properties of aluminum alloys are influenced by their composition, processing methods, and heat treatment.

Physical Properties

Physical properties describe a material’s inherent characteristics, such as its density and melting point.

- Density: Indicates a material’s mass per unit volume. Lightweight aluminum alloys are highly valued in construction for reducing structural weight.

- Melting Point: Indicates the temperature at which a material transitions from a solid to a liquid state. Aluminum has a relatively low melting point, making it easy to work with.

Understanding the mechanical and physical properties of aluminum alloys will help you select the best material for your specific application.

Cost Considerations for 5052 and 6061 Aluminum

Cost is a crucial factor in any construction project. 5052 aluminum is generally considered slightly more expensive than 6061 aluminum due to its higher magnesium content. However, its superior corrosion resistance and long-term durability can offset the initial cost difference.

Remember: Prices can fluctuate based on market conditions, product forms, and quantities.

Cozydoor: “We offer competitive pricing on our 5052 and 6061 aluminum products. Contact us for a customized quote tailored to your specific needs and budget.”

Now, equipped with this knowledge, you can confidently choose between 5052 and 6061 aluminum for your next construction project. Ready to take your building expertise to the next level? Contact Cozydoor today for personalized advice, product recommendations, and preferential pricing on high-quality aluminum solutions.

Let Cozydoor help you achieve construction success!

Fill out the form below for a free consultation with one of our experts. We’re here to guide you every step of the way.

7 Ways Aluminum Uses in Industry

Aluminum has become a cornerstone material across various industries, thanks [...]

Nov

Custom Aluminum Extrusions: Perfect Fit for Your Design Needs

Tired of the same old, cookie-cutter solutions for your industrial [...]

Nov

Discover the Different Types of Aluminum and Their Uses

The right aluminum can elevate your construction to new heights, [...]

Nov

Power of Aluminium Die Casting

Are you a construction professional looking to optimize your projects [...]

Nov

5 Types of Anodizing to Elevate Your Construction Projects

Understanding the Different Types of Anodizing Anodizing is an electrochemical [...]

Nov

7 Proven Ways Aluminum Foil Material Elevates Your Projects

This comprehensive guide unveils seven ways aluminum foil material can [...]

Nov

Mastering the Conductivity of Al for Optimal Project Success

One key factor often overlooked is the strategic selection of [...]

Nov

Unlocking the Secrets of Aluminum Ore: What is Bauxite?

Cozydoor, your trusted partner in construction materials, is here to [...]

Nov